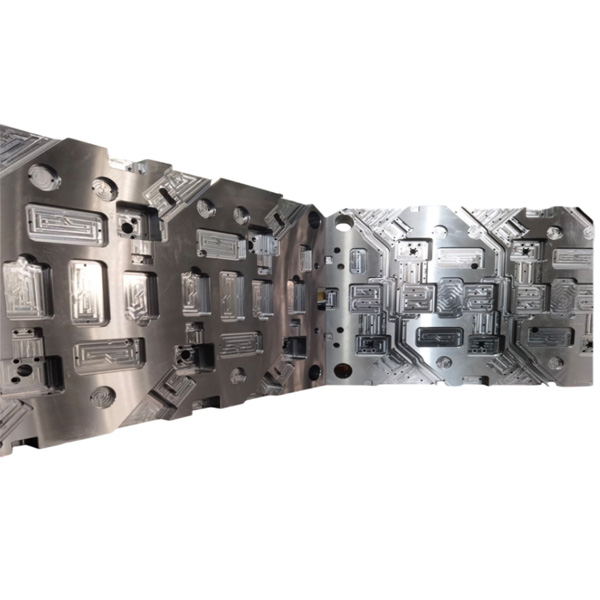

Precision mold

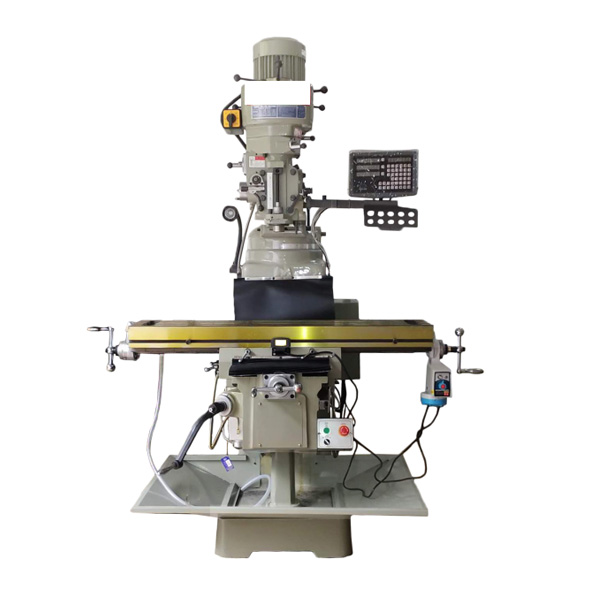

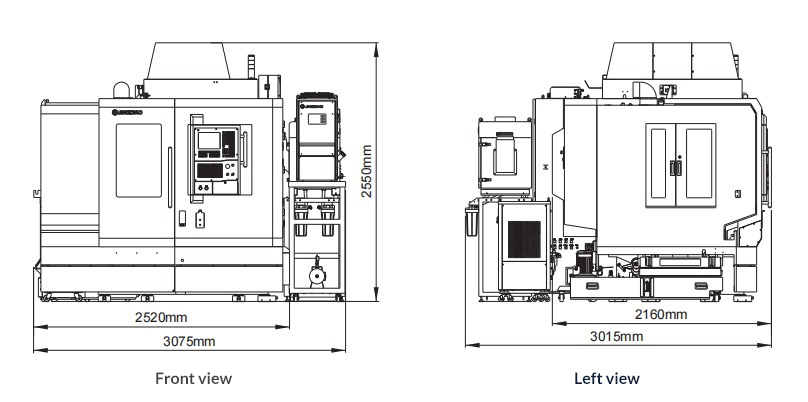

Standard equipment

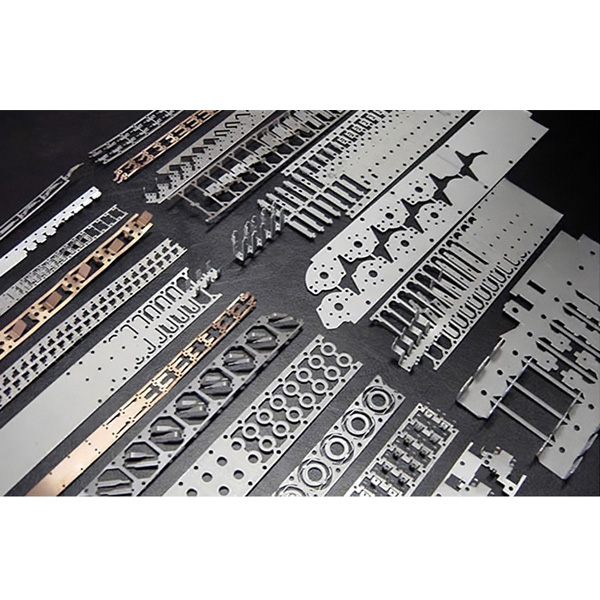

Stamping

Injection molding

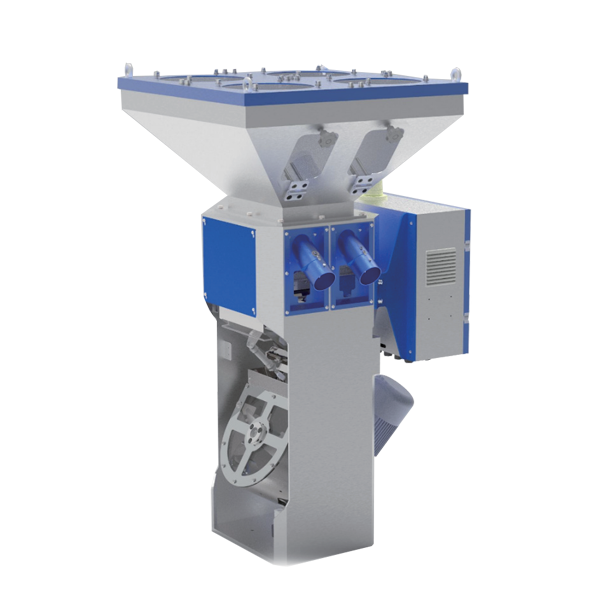

Auxiliary equipment

Standard equipment

Standard parts

Auxiliary equipment

Consumables

Tireey Connector

-

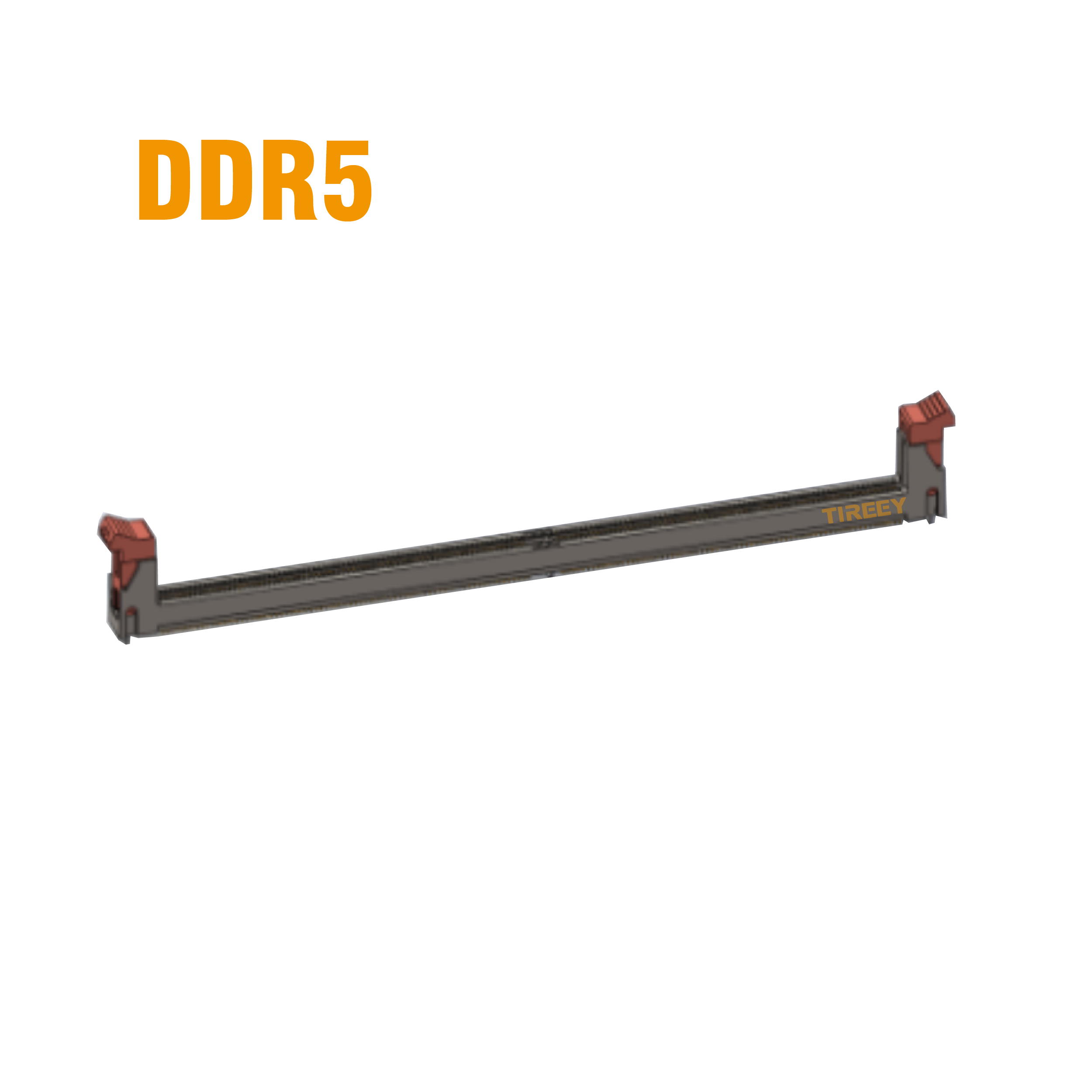

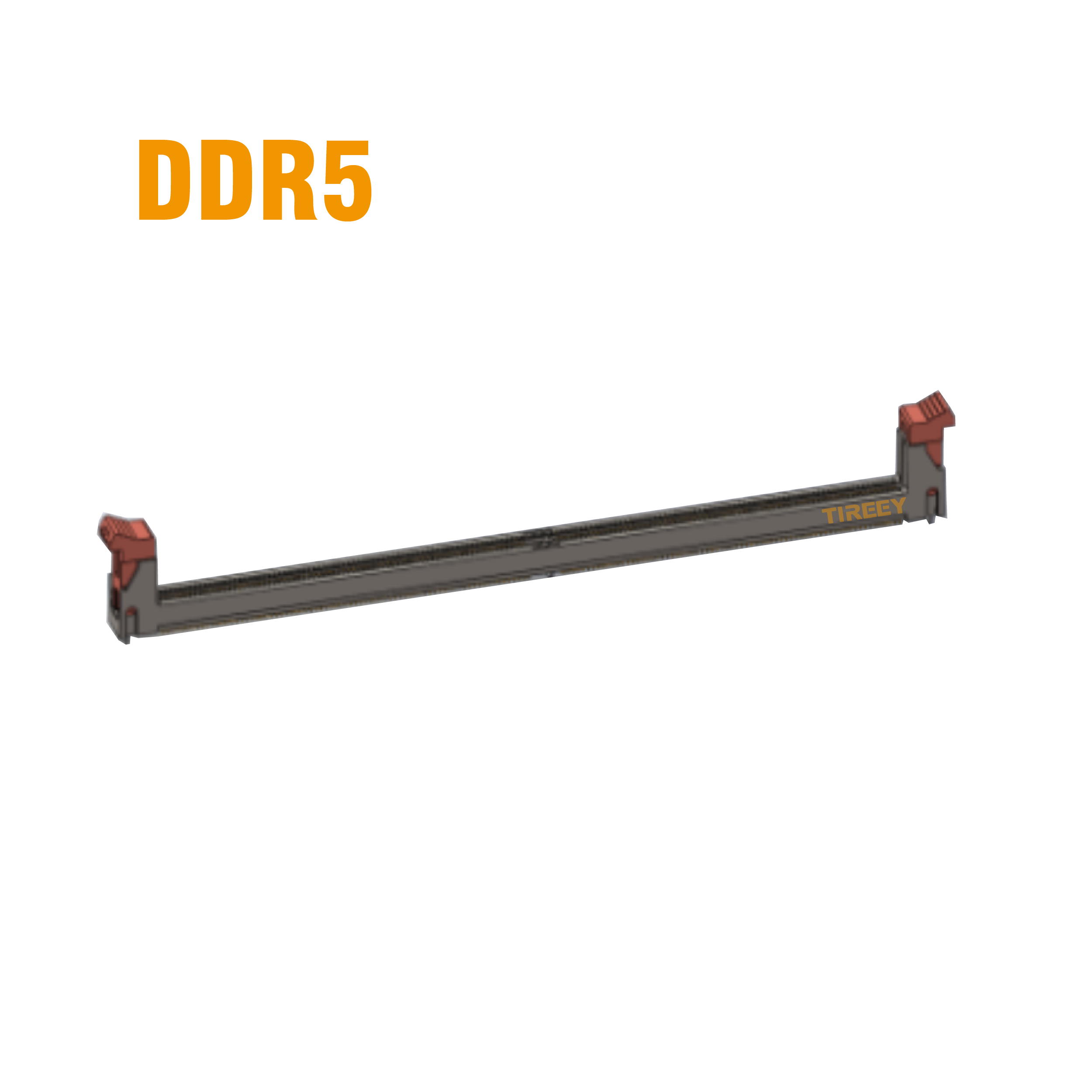

DDR5 288Pin Vertical SMT+DIP 20.6H

DDR5 288Pin Vertical SMT+DIP 20.6H -

DDR5 288Pin Vertical SMT+DIP 20.6H Single buckle specification

DDR5 288Pin Vertical SMT+DIP 20.6H Single buckle specification -

DDR5 SO DIMM 262Pin STD 5.2H

DDR5 SO DIMM 262Pin STD 5.2H -

DDR5 SO DIMM 262Pin RVS 8.0H

DDR5 SO DIMM 262Pin RVS 8.0H -

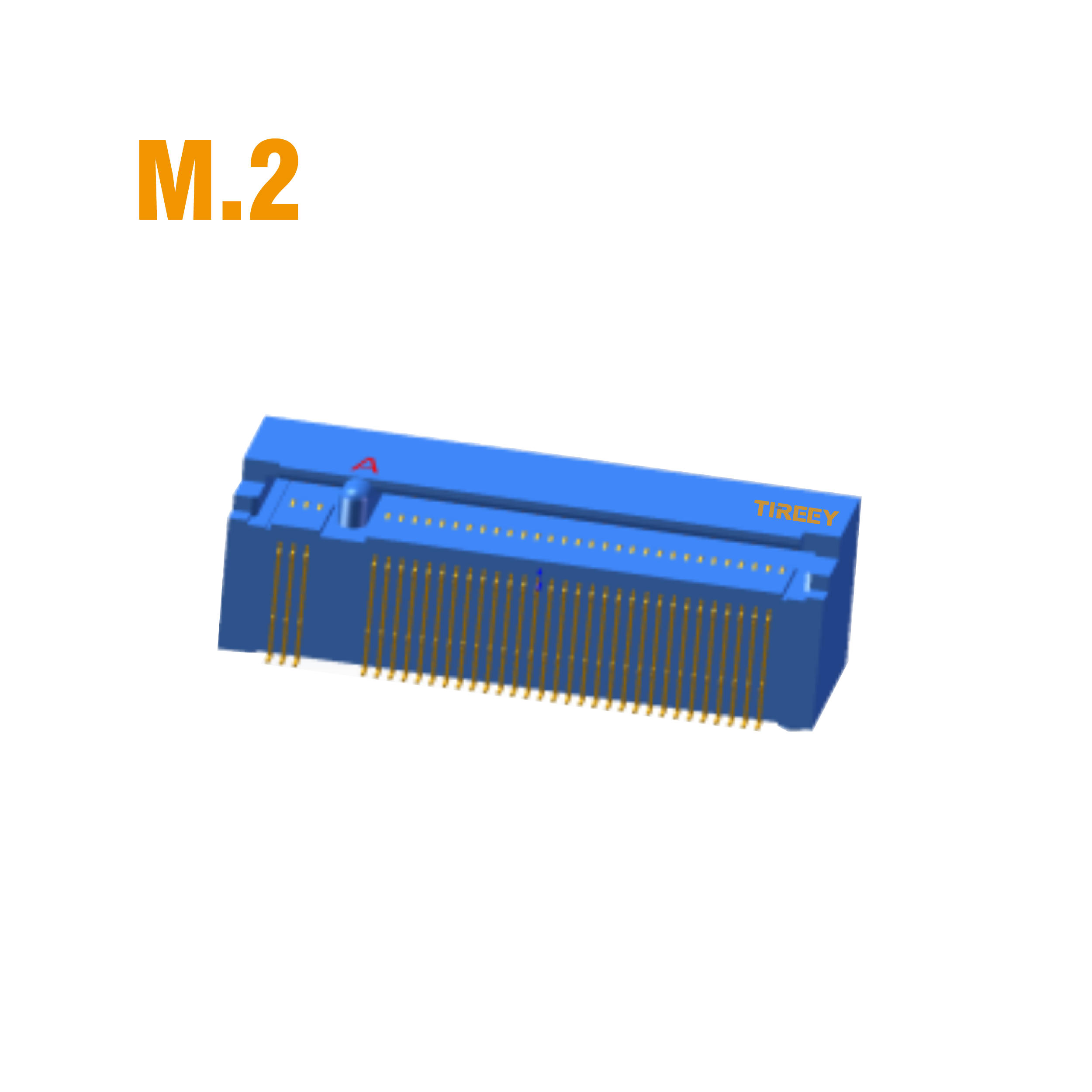

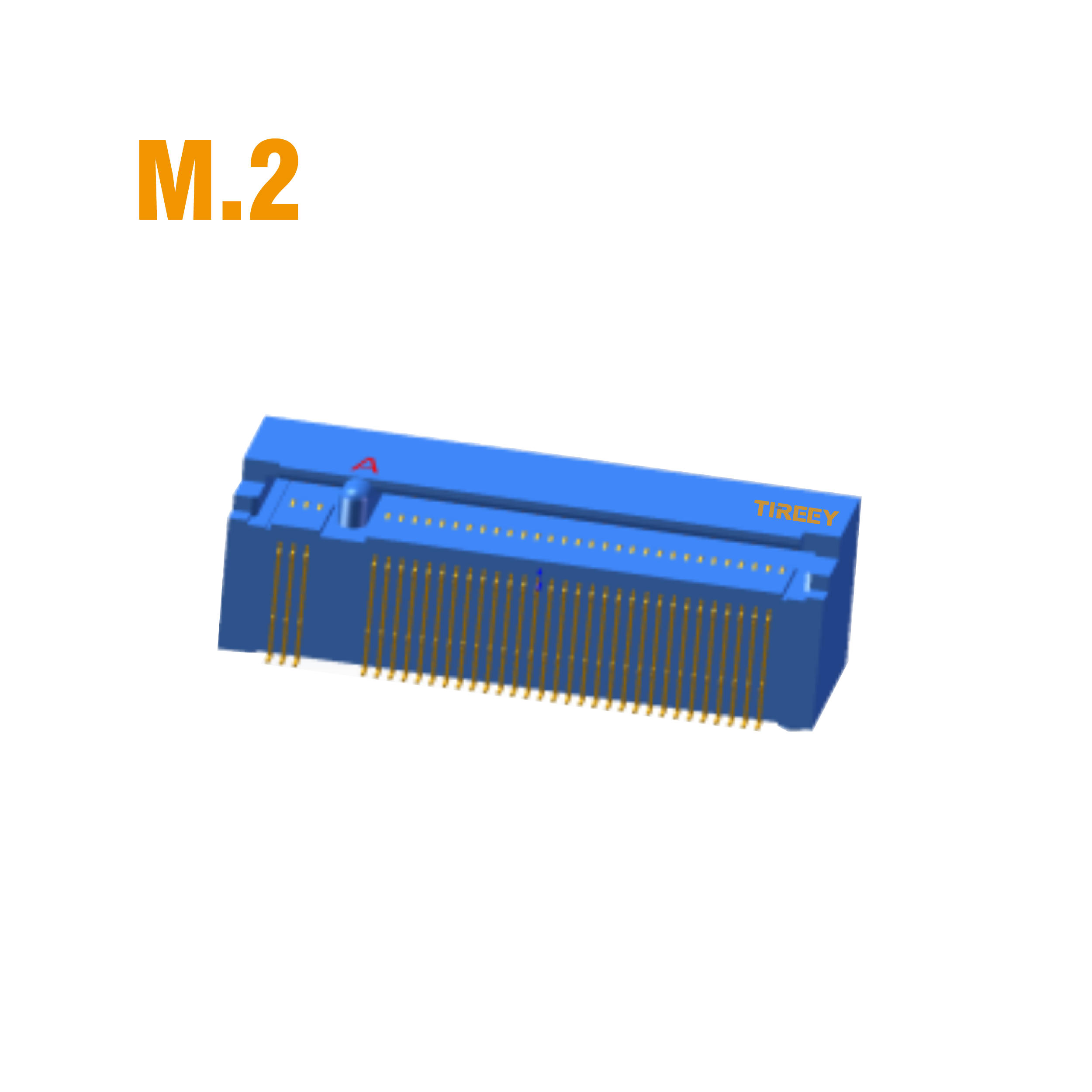

M.2 GEN4 H=8.5 A KEY CONN

M.2 GEN4 H=8.5 A KEY CONN -

M.2 GEN4 H=4.0 M KEY CONN

M.2 GEN4 H=4.0 M KEY CONN -

M.2 GEN4 H=4.0 E KEY CONN

M.2 GEN4 H=4.0 E KEY CONN -

DDR4 288PIN DIP

DDR4 288PIN DIP -

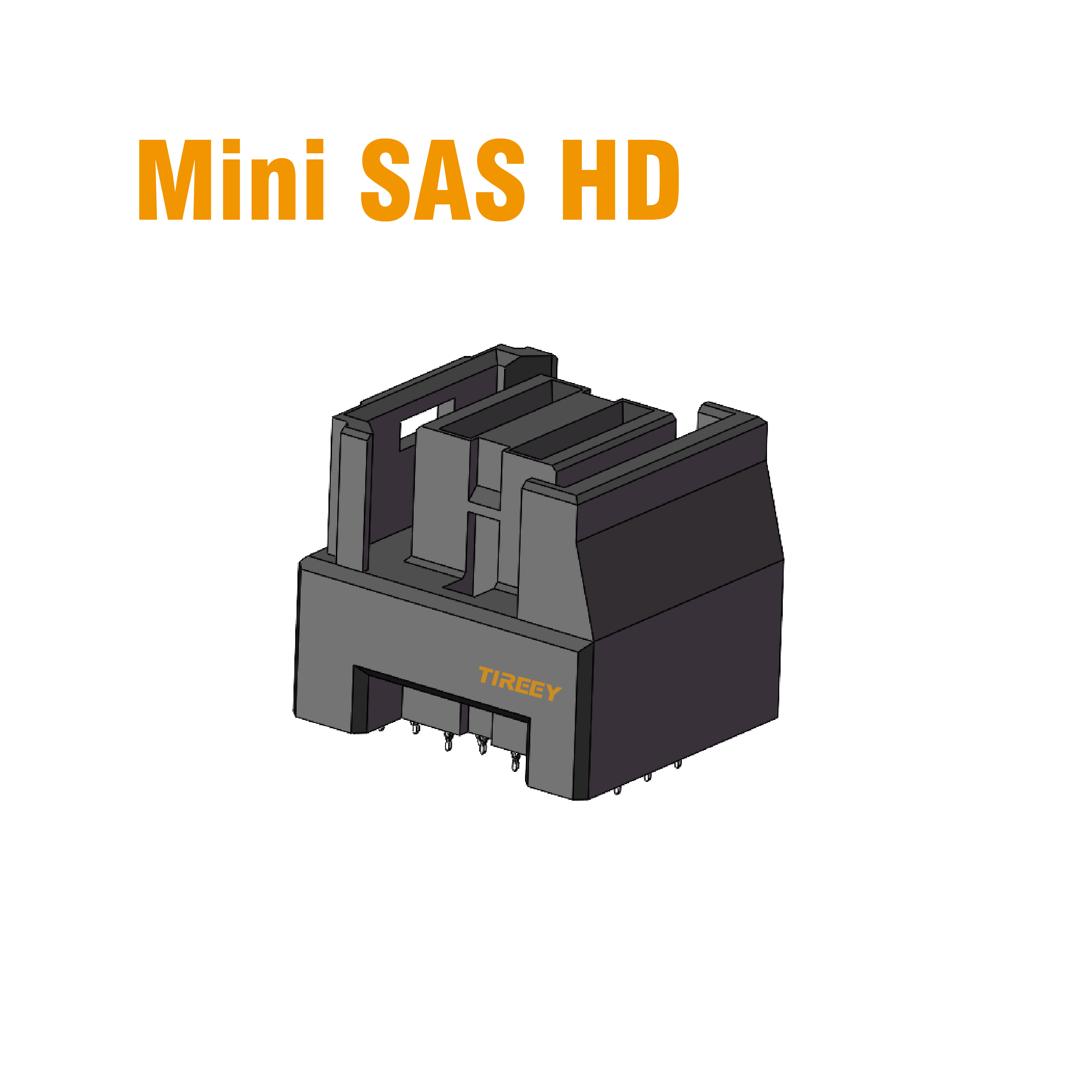

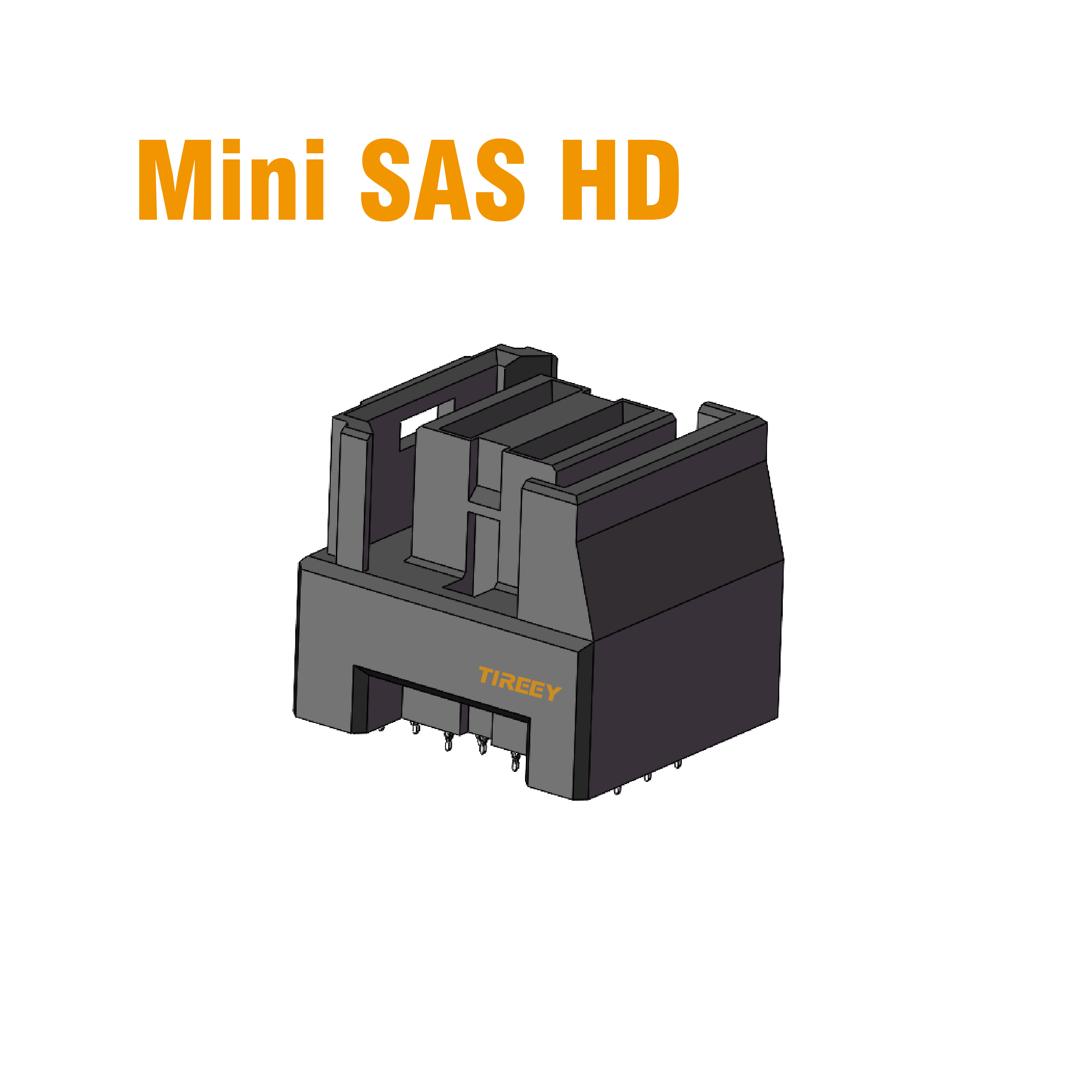

Mini SAS HD Vertical 36P Conn

Mini SAS HD Vertical 36P Conn -

PCIE4.0 8X 98Pin SMT type

PCIE4.0 8X 98Pin SMT type -

PCIE4.0 16X 164Pin Tail + Iron Case DIP Type

PCIE4.0 16X 164Pin Tail + Iron Case DIP Type -

PCIE5.0 16X 164Pin SMT type

PCIE5.0 16X 164Pin SMT type -

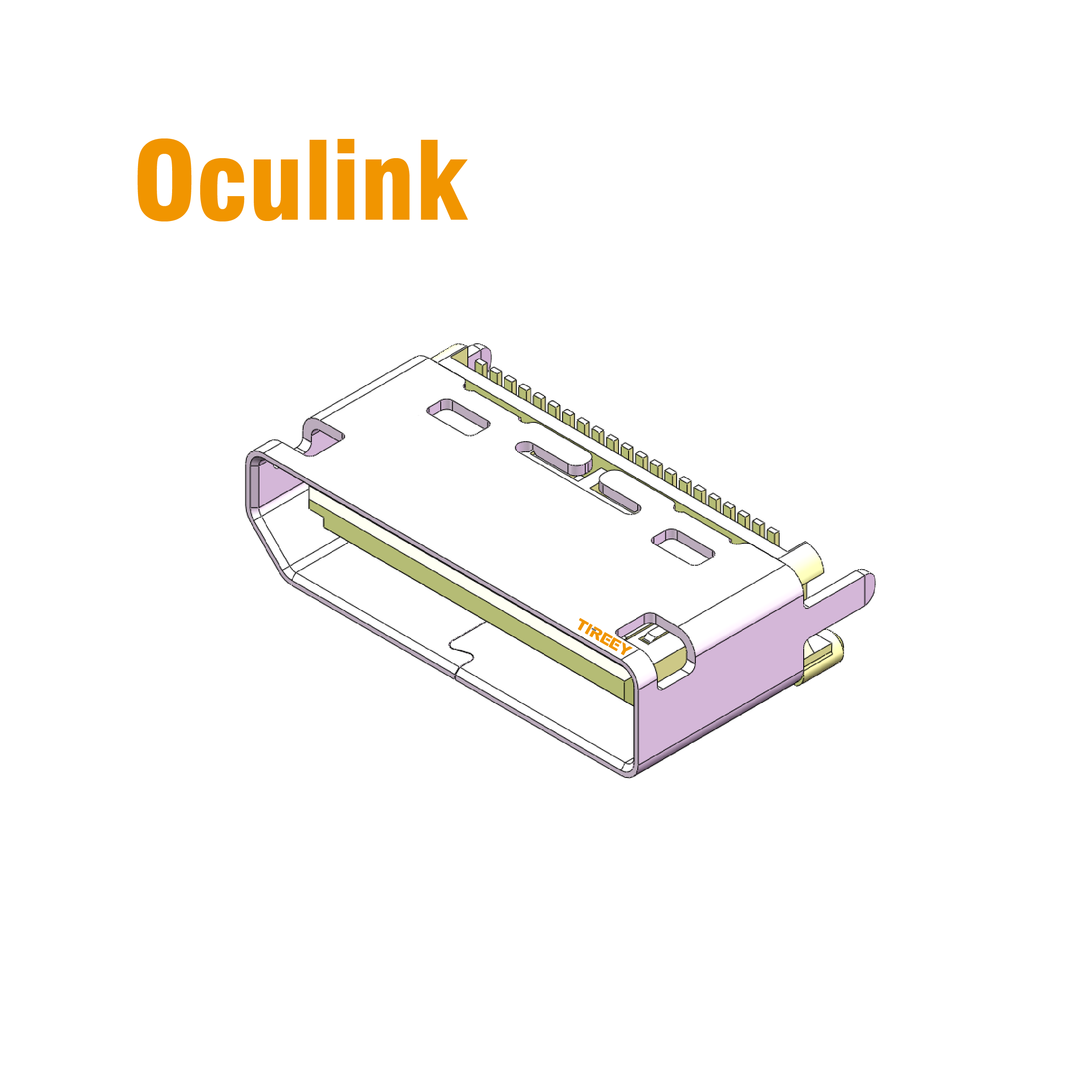

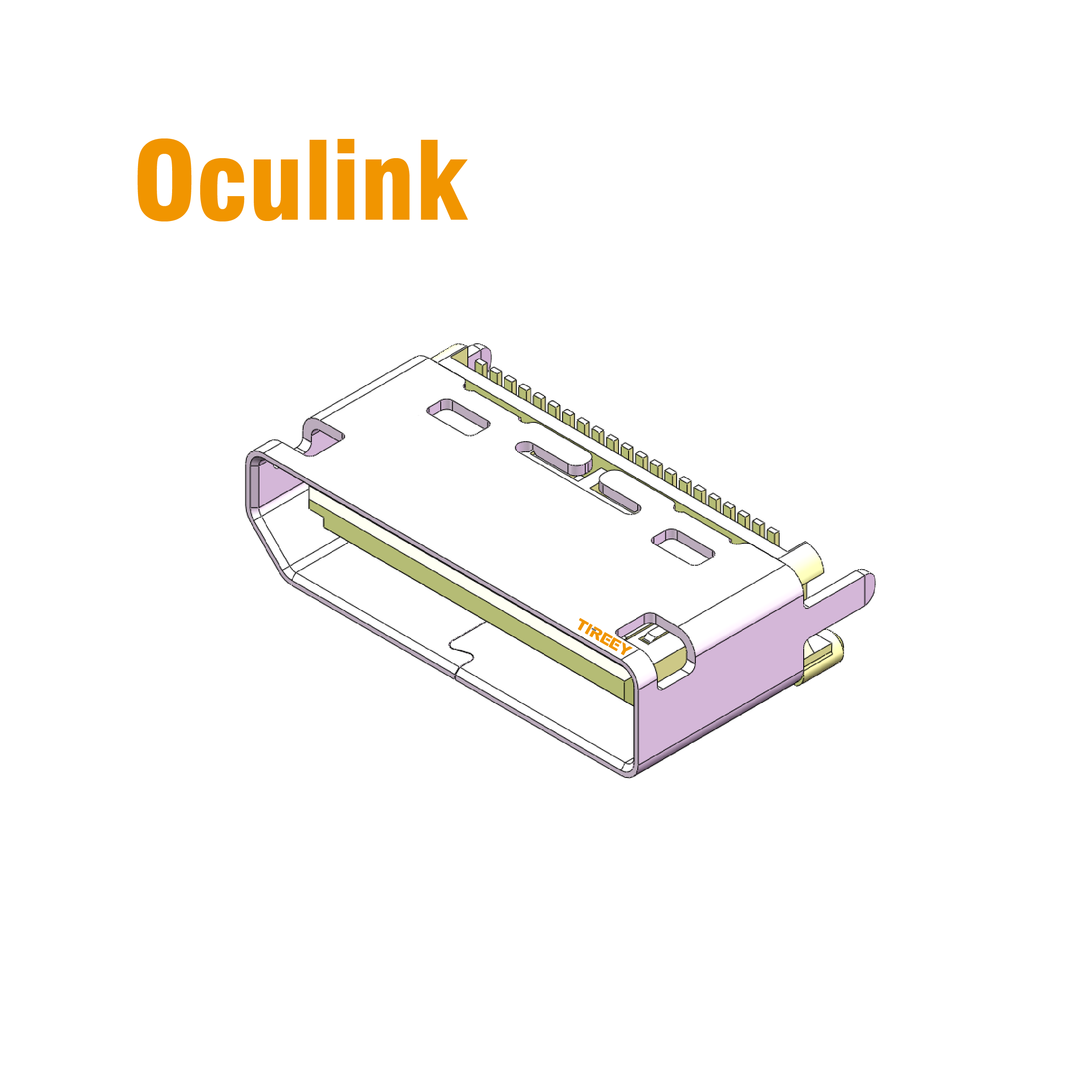

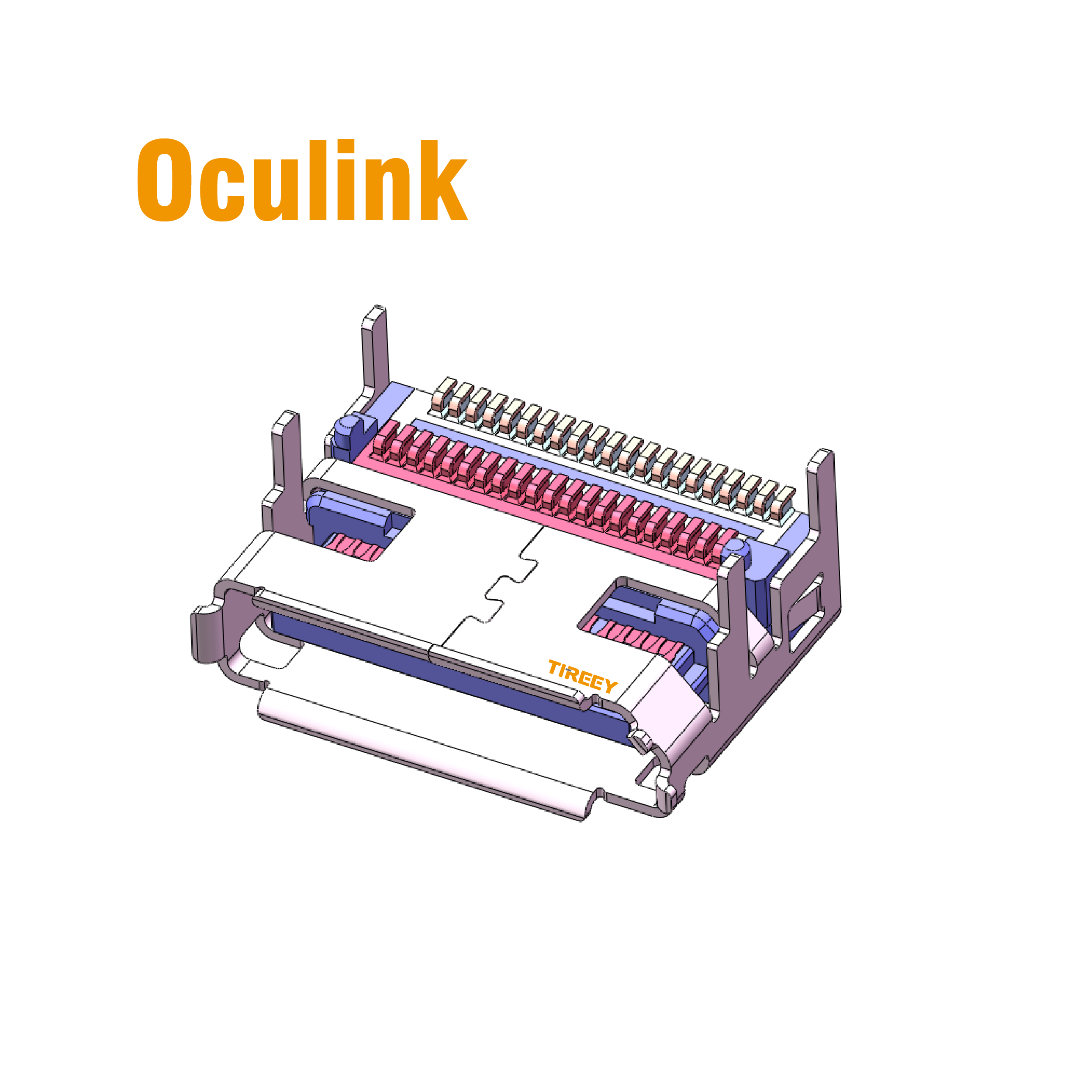

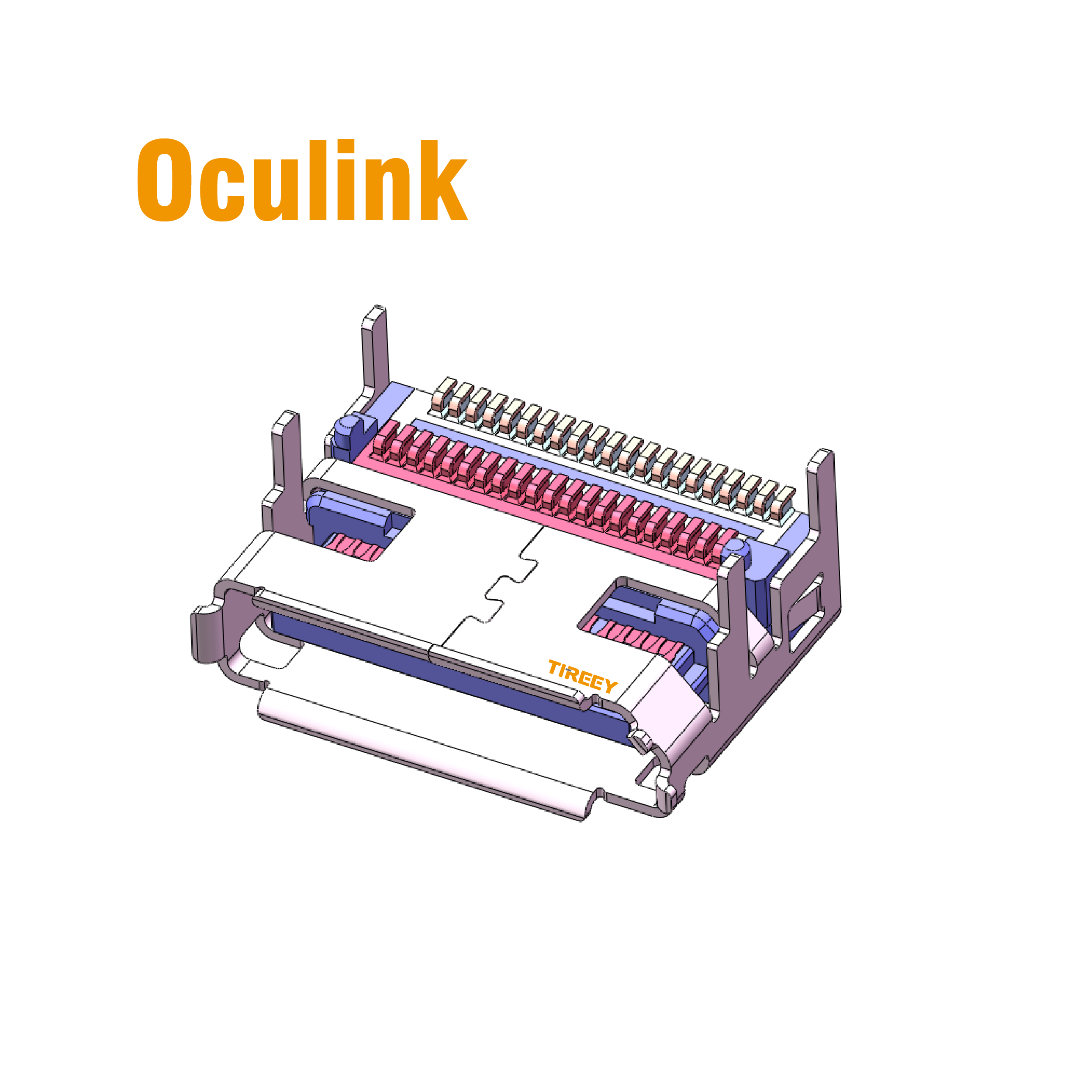

Oculink V/T 4x conn

Oculink V/T 4x conn -

Oculink R/A 4x conn

Oculink R/A 4x conn -

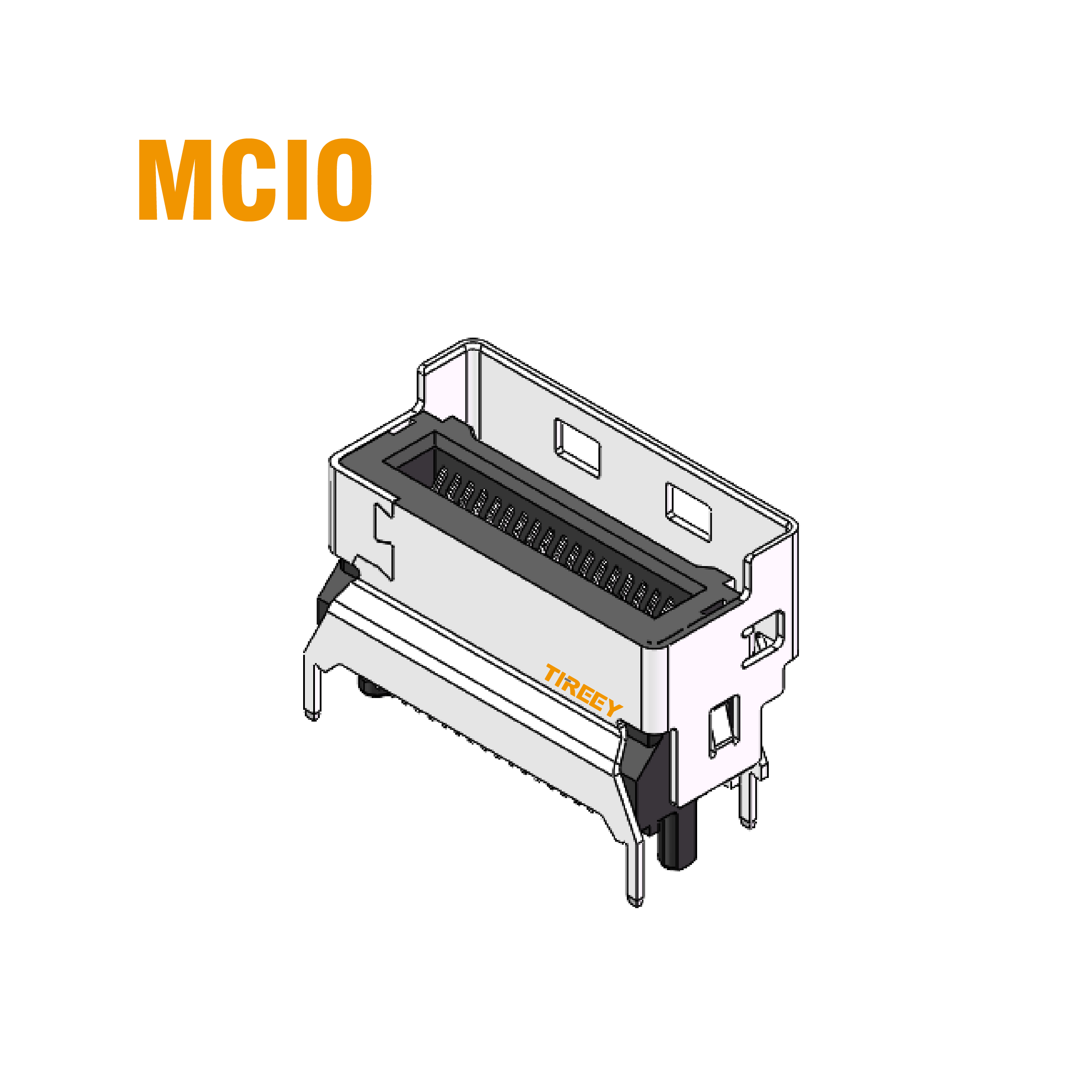

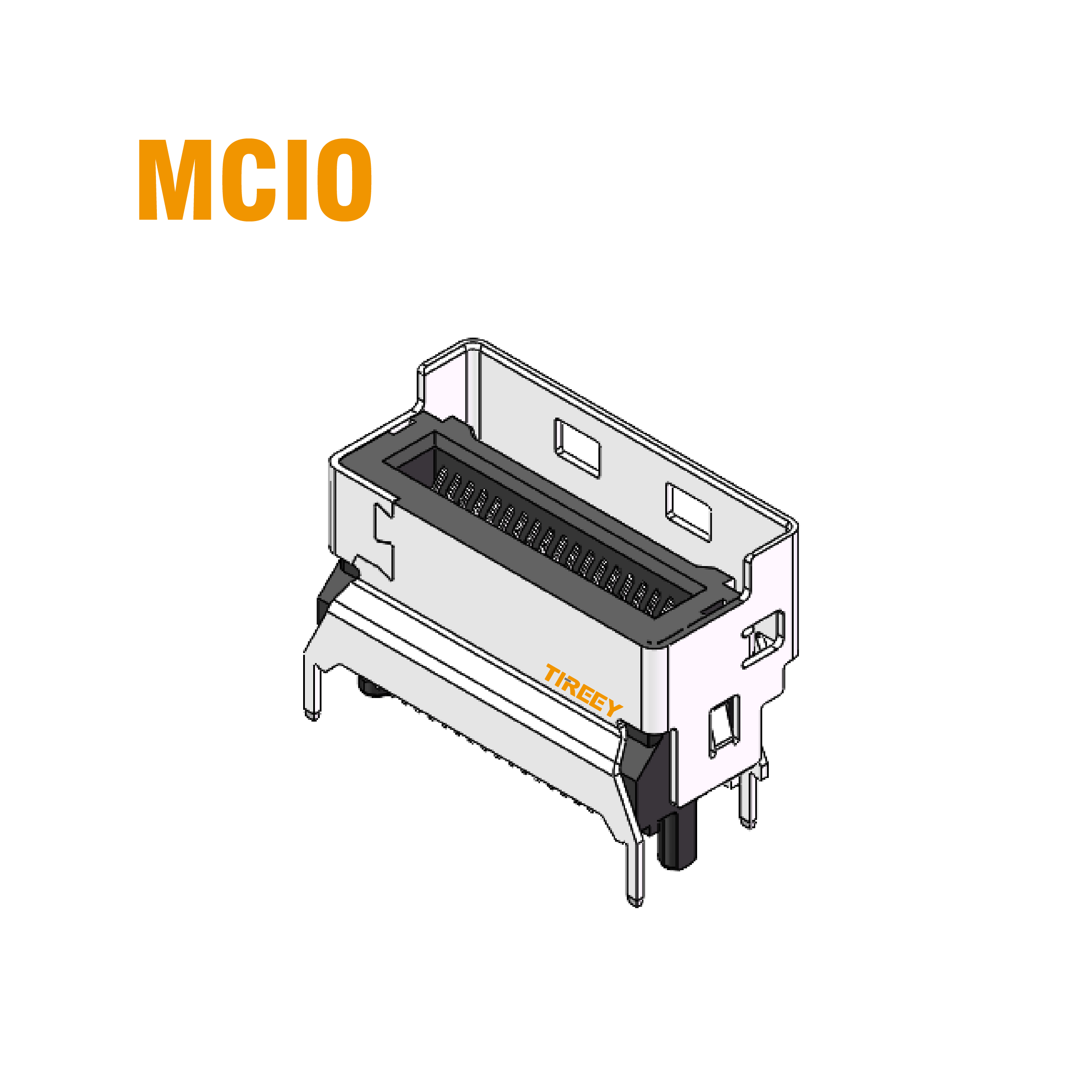

MINI COOL 38Pin 4X Vertical Conn

MINI COOL 38Pin 4X Vertical Conn -

MINI COOL 74Pin 8X Horizontal Conn

MINI COOL 74Pin 8X Horizontal Conn -

MINI COOL 74Pin 8X vertical Conn

MINI COOL 74Pin 8X vertical Conn -

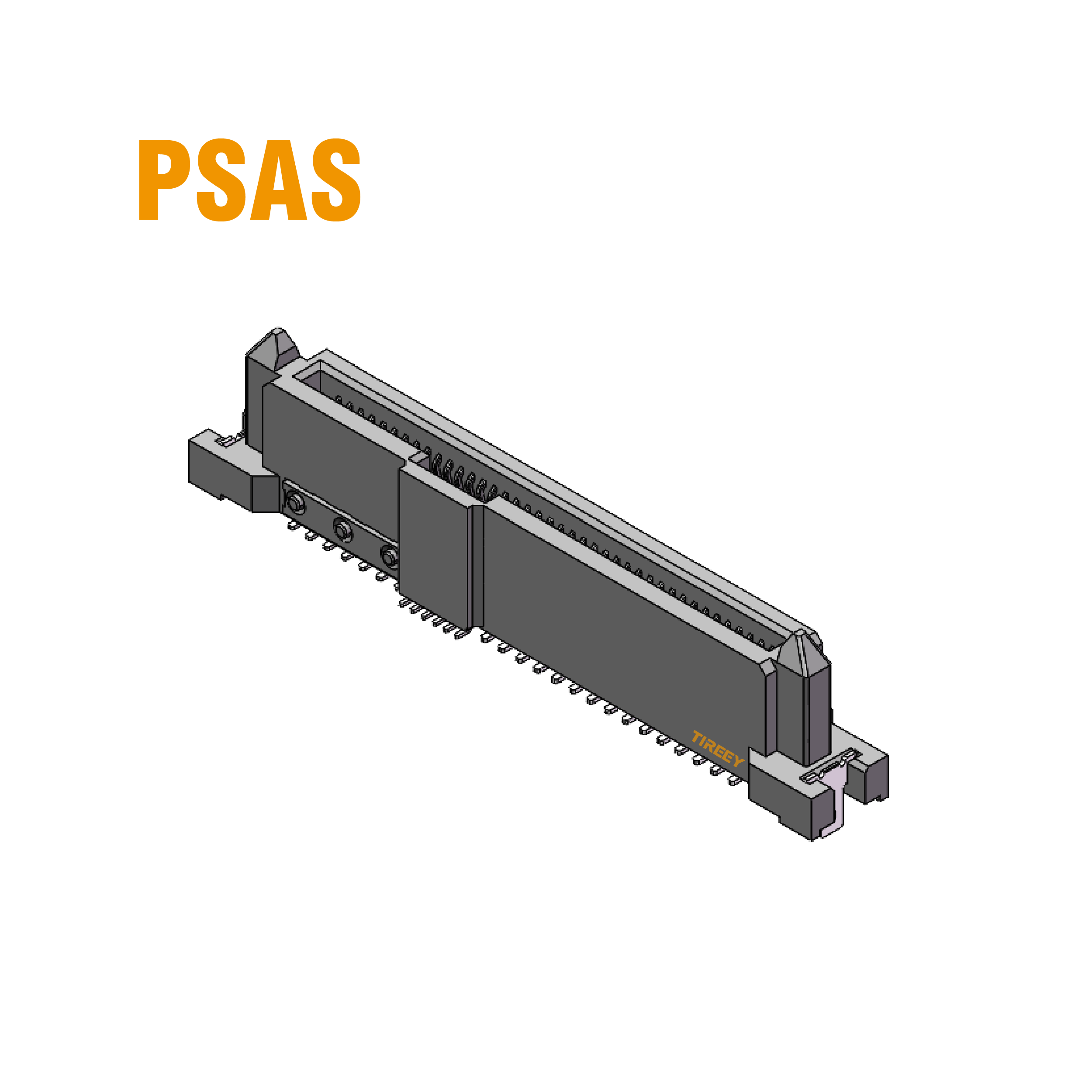

PSAS 68Pin for 24G PCIe/SAS

PSAS 68Pin for 24G PCIe/SAS -

PSAS 68Pin for Pcle 5.0 Specification

PSAS 68Pin for Pcle 5.0 Specification -

PSAS 68Pin for Pcle 5.0 Specification

PSAS 68Pin for Pcle 5.0 Specification -

Gen Z4C + Vertical 168Pin

Gen Z4C + Vertical 168Pin -

Gen Z4C + Splint Type 168Pin

Gen Z4C + Splint Type 168Pin -

GenZ4C Vertical 140Pin No Iron Case

GenZ4C Vertical 140Pin No Iron Case -

GenZ4C + Vertical 168Pin + Iron Case

GenZ4C + Vertical 168Pin + Iron Case -

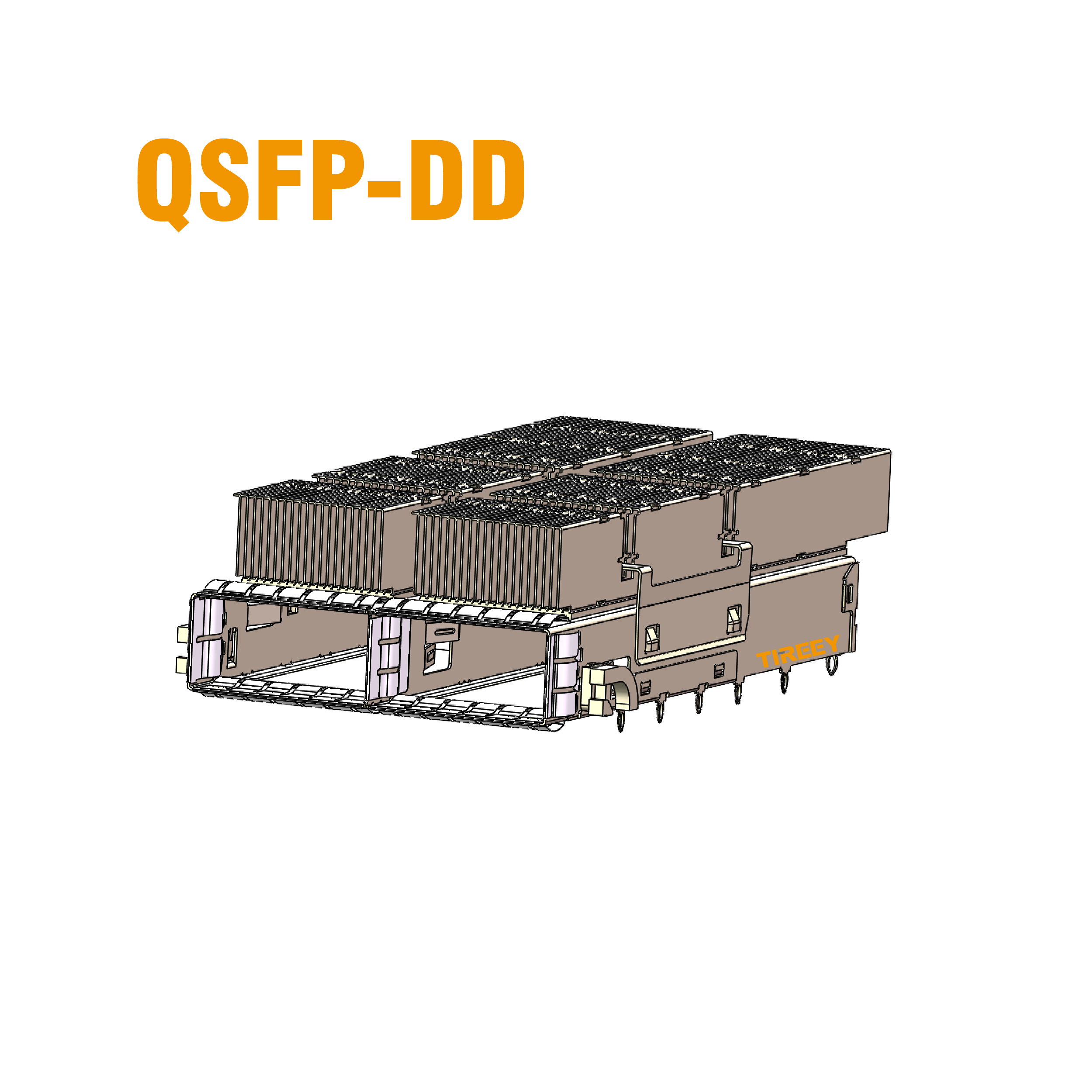

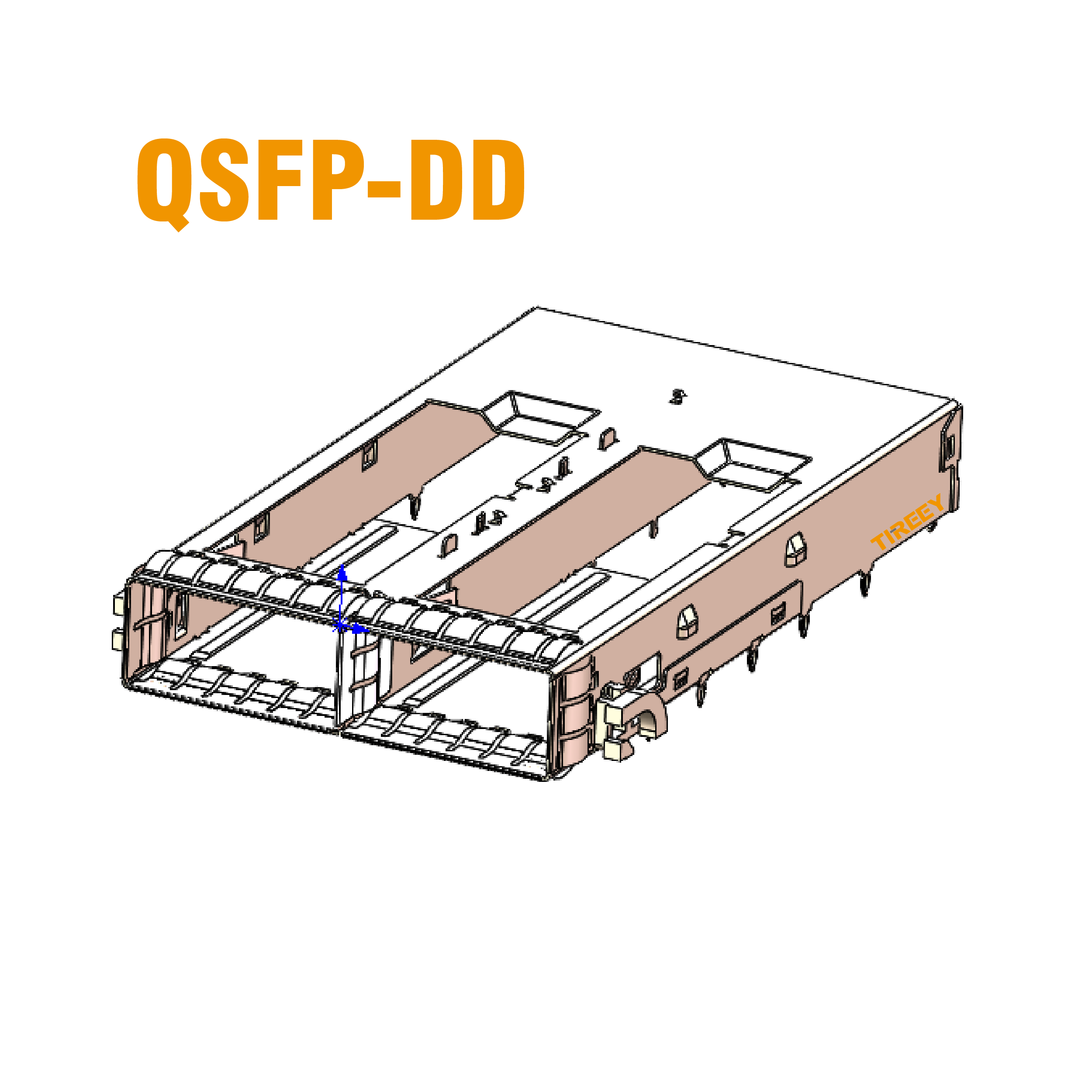

QSFP-DD 1*2 + Radiator

QSFP-DD 1*2 + Radiator -

QSFP-DD 1*2 Cage

QSFP-DD 1*2 Cage -

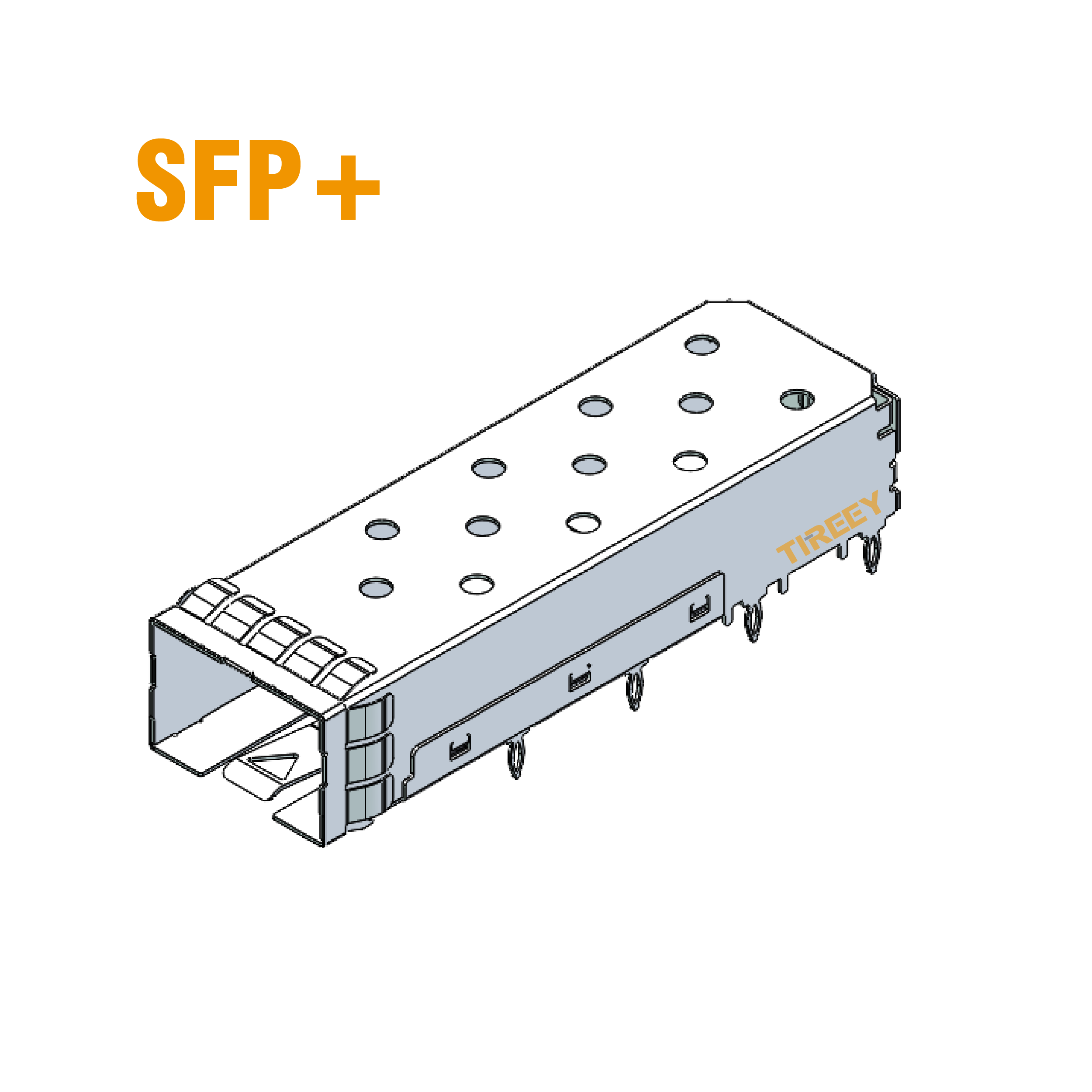

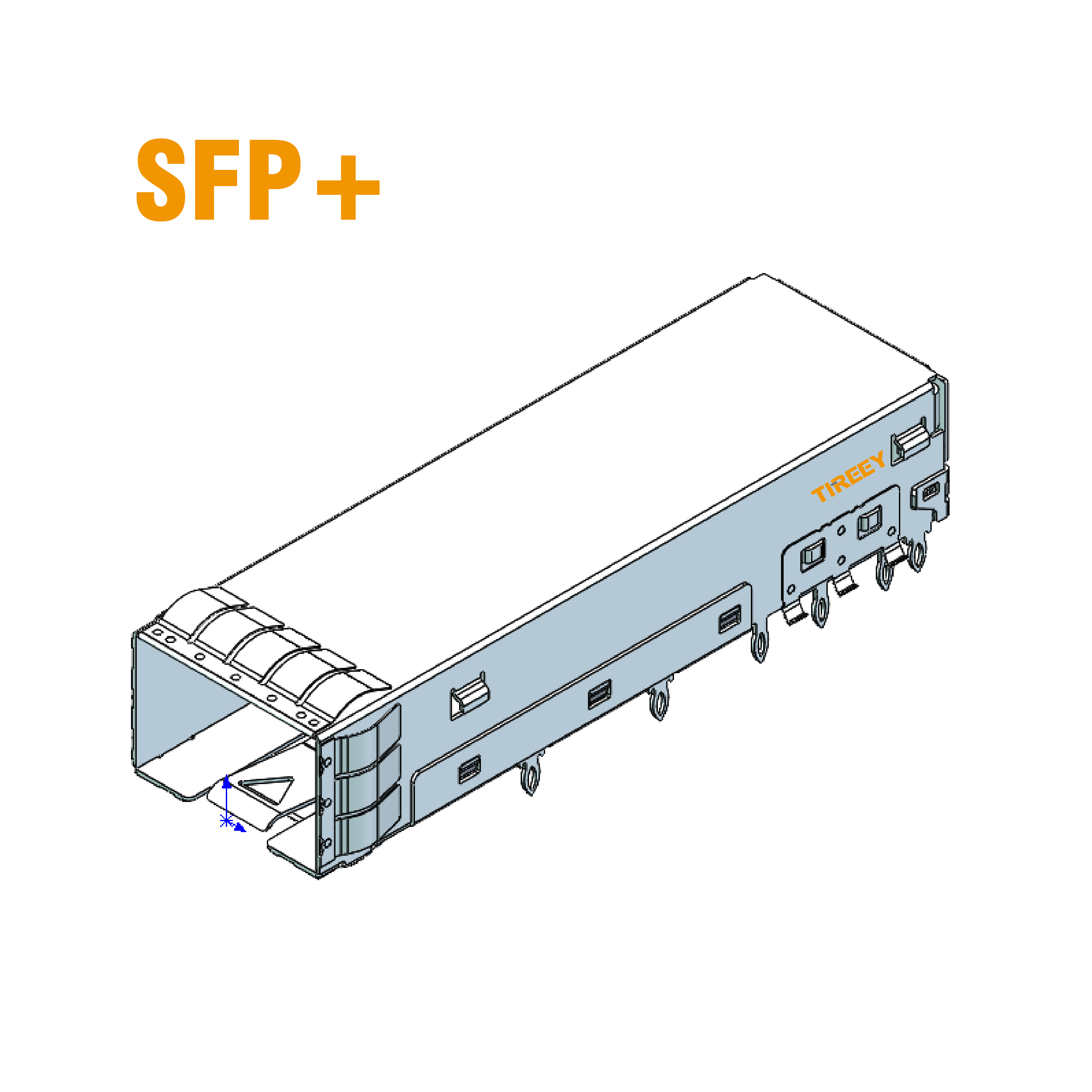

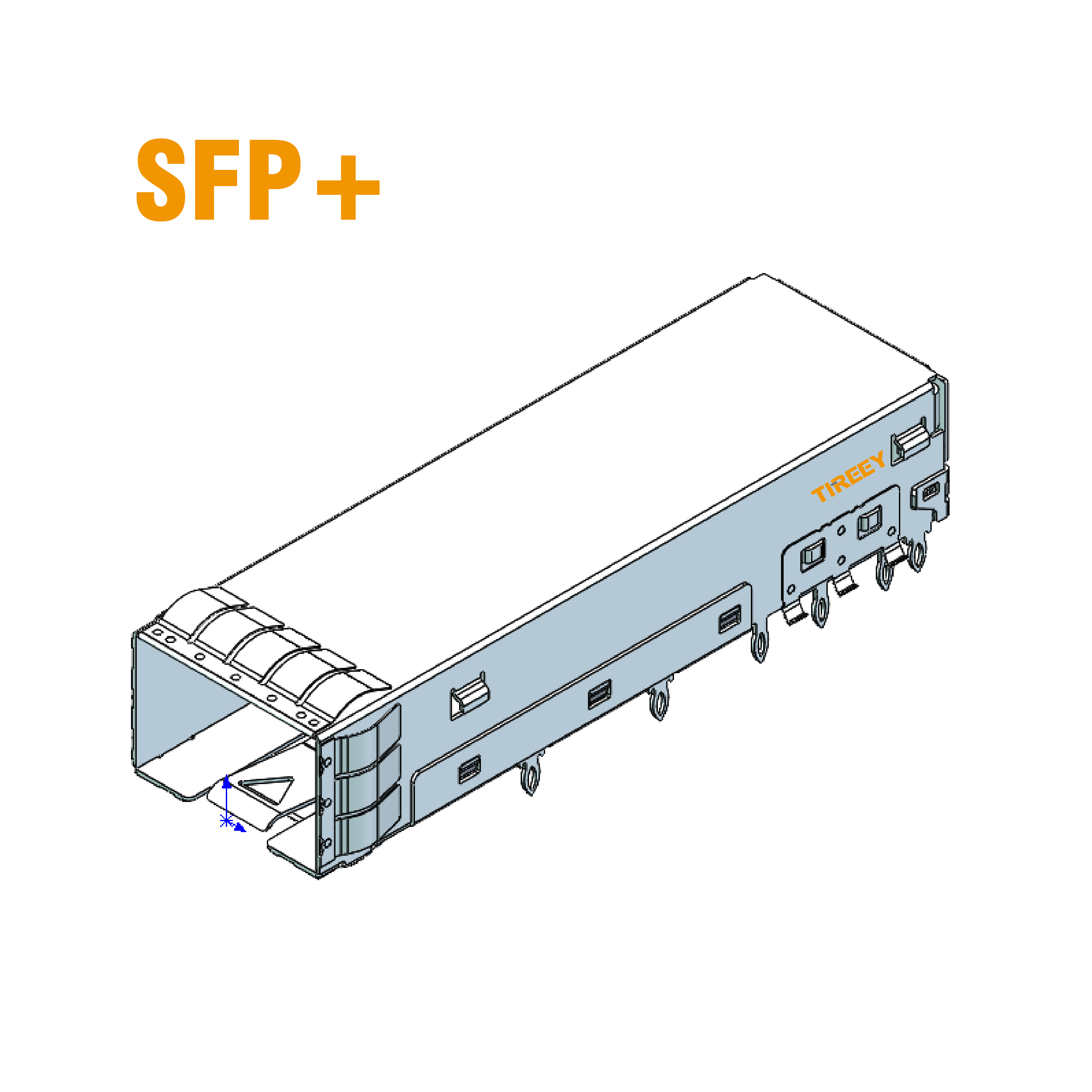

SFP+1*1 Crimp Pin

SFP+1*1 Crimp Pin -

SFP28 1*1 Crimping With Double-sided Spring Clip

SFP28 1*1 Crimping With Double-sided Spring Clip