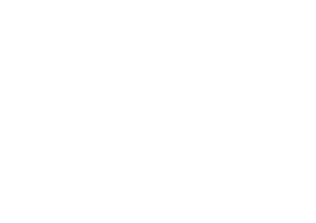

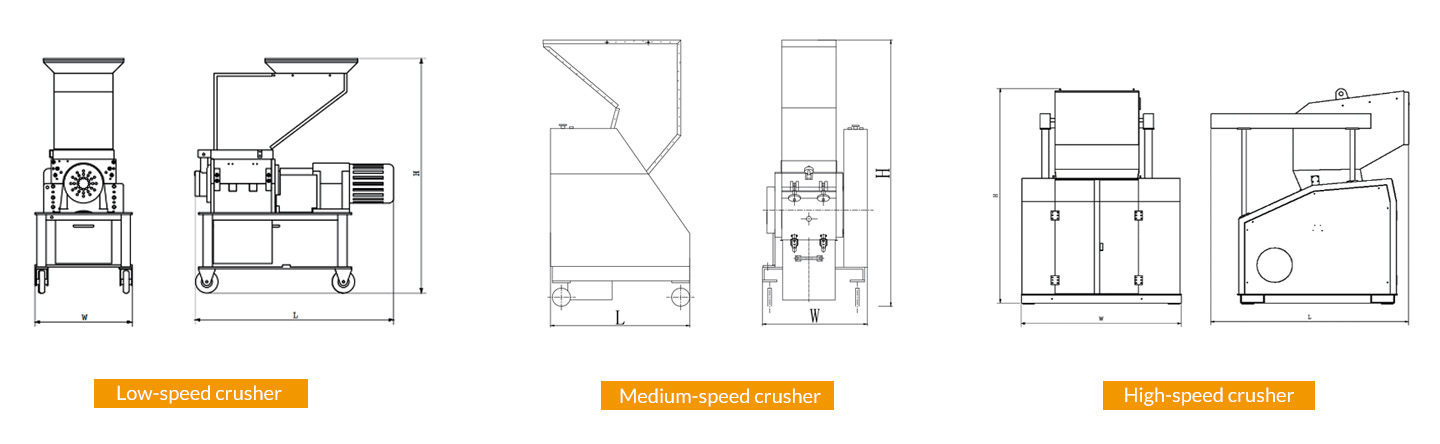

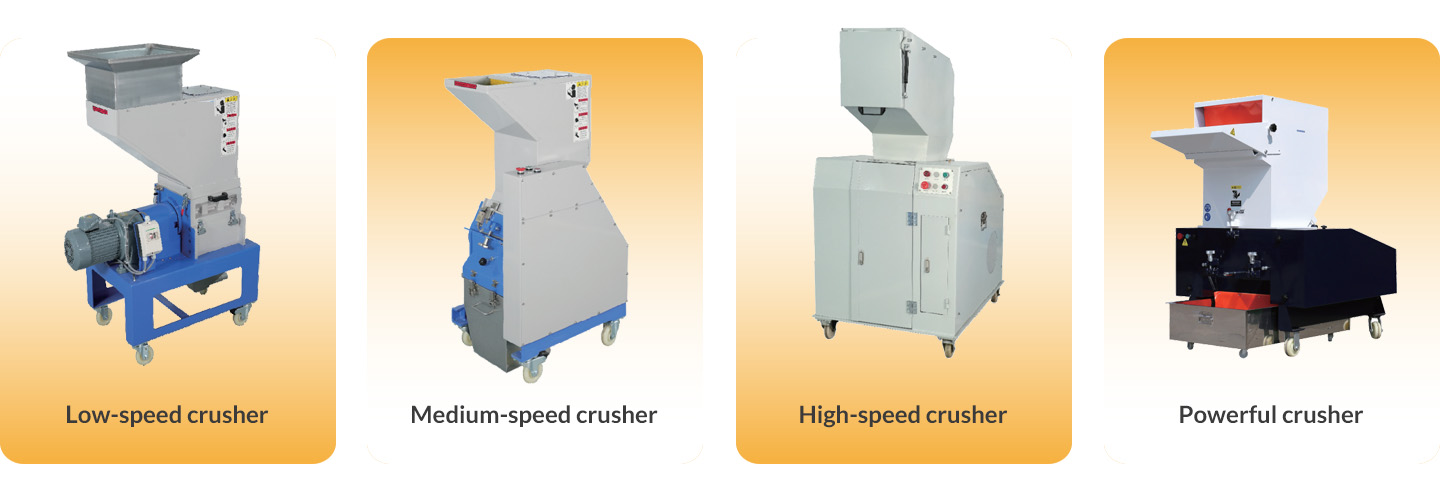

Low-speed crusher

■ Suitable for crushing and recycling of degraded materials around injection molding machines, with silent design

■ No sieve mesh, no missed cutting, and good particle size, with little powder

■ Adopting newly designed cutters to provide stable crushing and reduce crushing load

■ With easy-to-clean design, the cleaning unit can be pulled out from the front directly for cleaning, reducing maintenance space

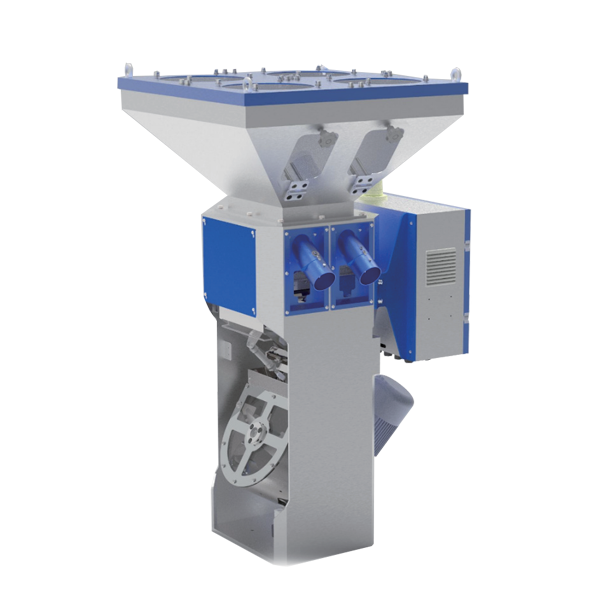

Medium-speed crusher

■ Electrical configuration: equipped with start, stop, emergency stop buttons, main power control switch, motor overload protection switch, and safety protection switch for feed bin and recycling bin

■ Cyclone dust collector: It can effectively separate the crushed materials and dust, facilitating the effective utilization of raw materials

■ Dust collection bag: easy to clean, reducing pollution

■ Feeding blower device: It can achieve automatic feeding and improve utilization efficiency

■ Full material alarm device: When the crushed material in the bin reaches the set full material position, the machine automatically stops working and alarms the user

■ Special sieve mesh aperture: ¢4, ¢8, ¢10, ¢12, users can choose according to actual needs

■ New and old material mixing ratio valve: It can adjust the mixing ratio of new and old materials according to production needs

■ Magnetic adsorption: It can effectively prevent various iron debris from entering the crushing chamber from the feed inlet, preventing metal objects from damaging the machine

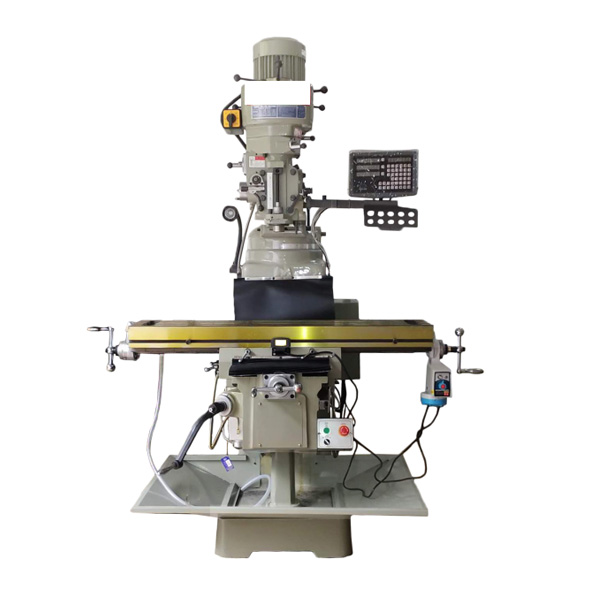

High-speed crusher

■ It is suitable for concentrated crushing of materials, material rods, die materials, etc. Widely used in various fields

Powerful crusher

■ The motor is equipped with an overload protection device and a power side lock protection device, ensuring absolute safety during operation and cleaning

■ Easy-to-detach design, with the feed hopper, powder knife, and filter screen can all be disassembled

■ Unique design minimizes horsepower and maximizes results, and the double-layer design reduces noise

■ When crushing transparent and white materials, please order the feed hopper and the mesh to be made of stainless steel to prevent the paint from peeling off during crushing

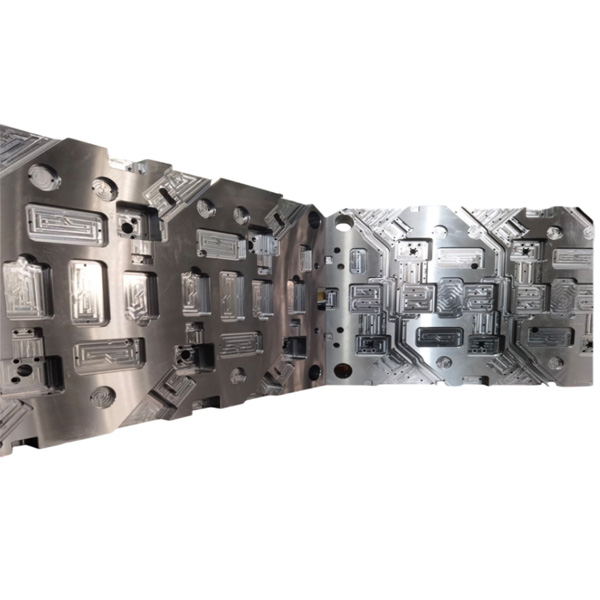

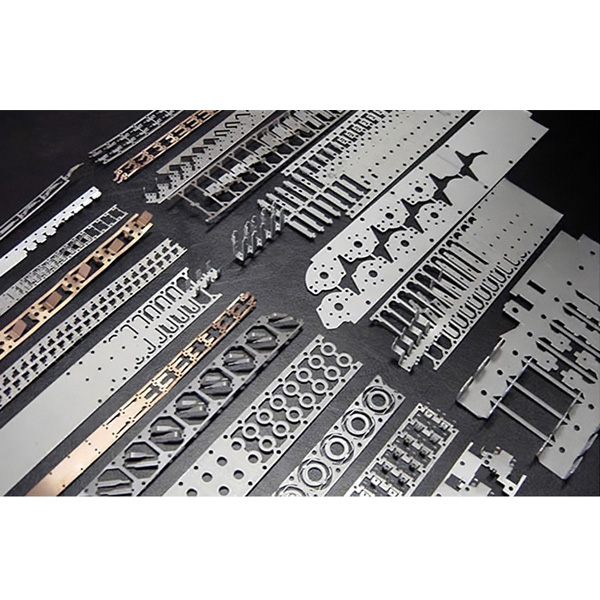

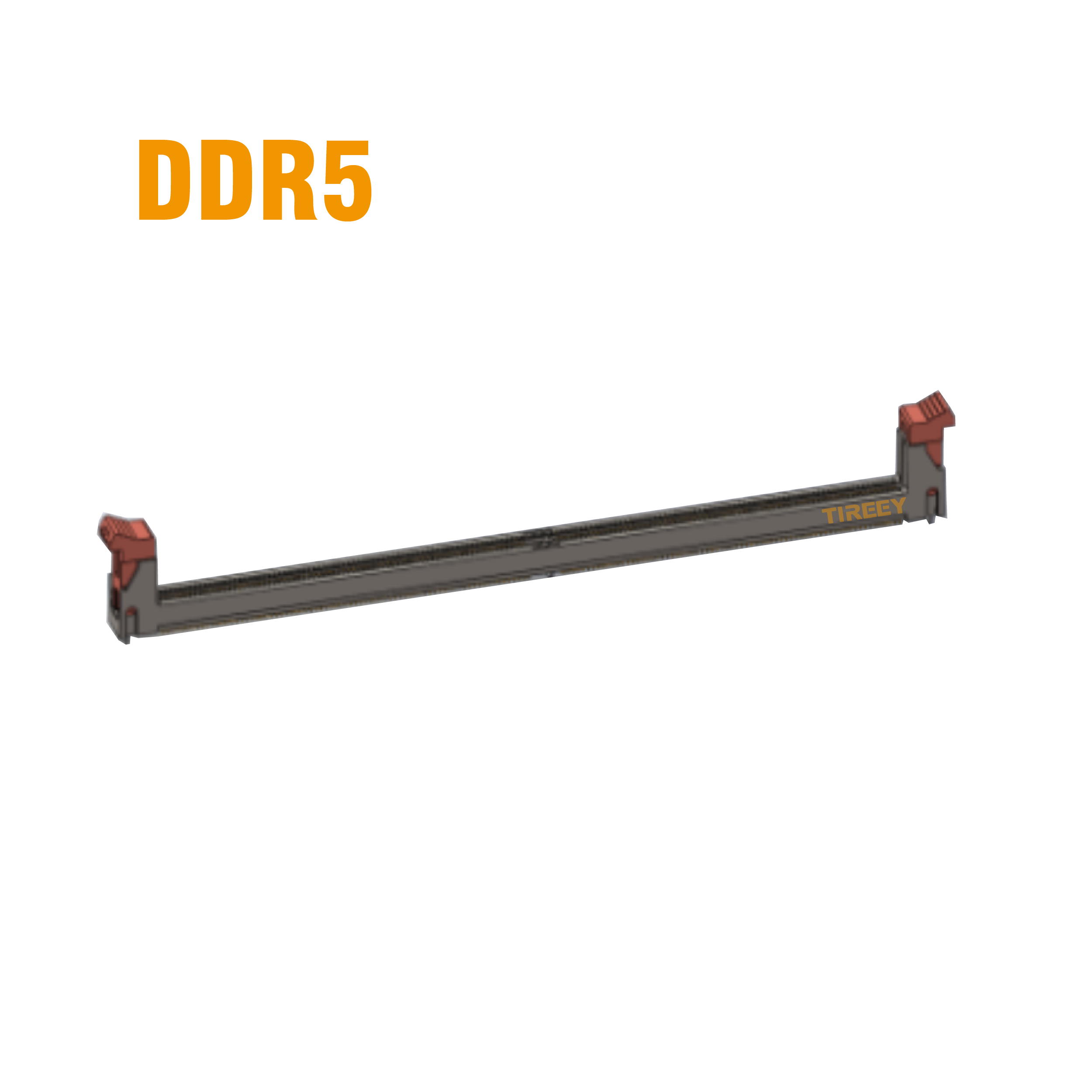

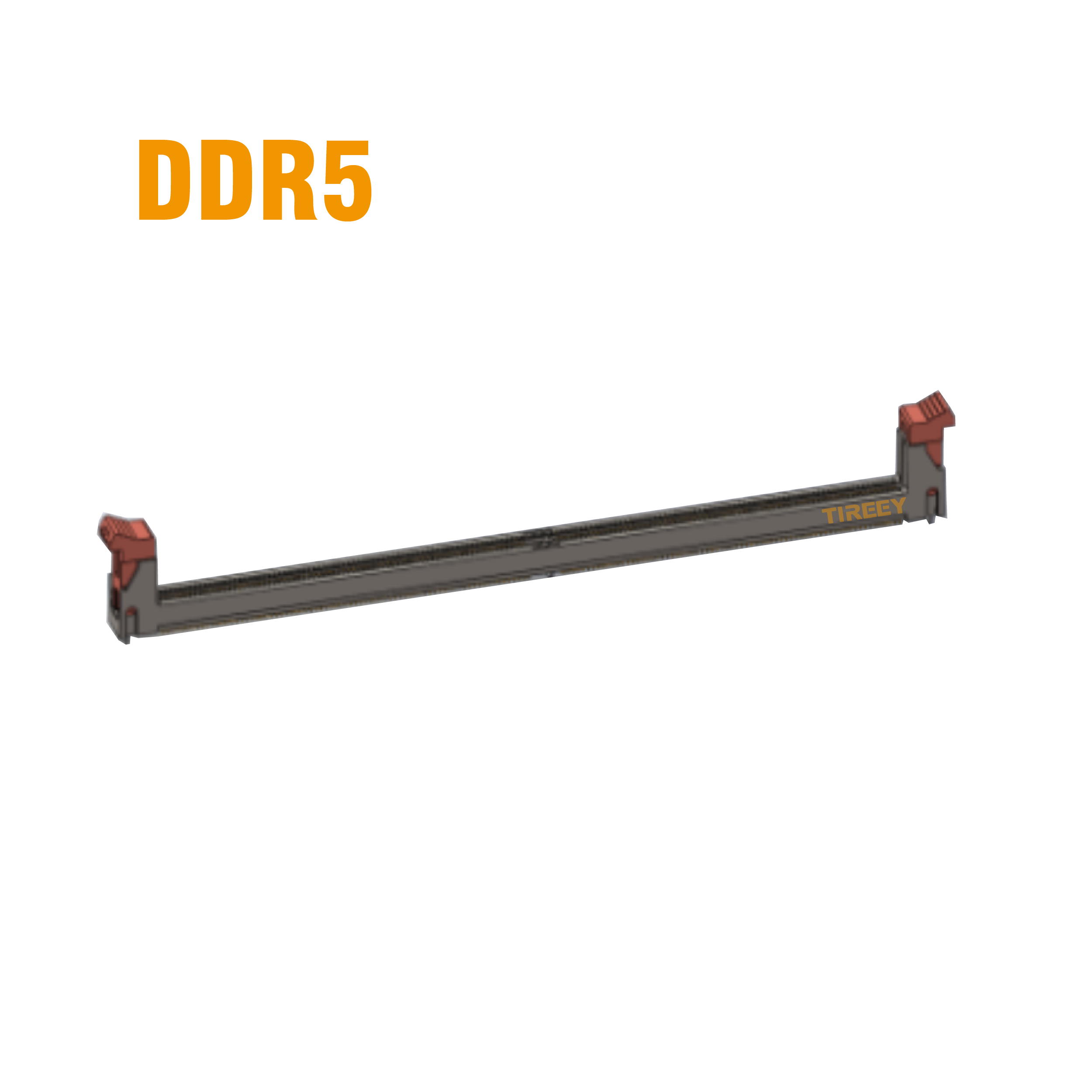

DDR5 288Pin Vertical SMT+DIP 20.6H

DDR5 288Pin Vertical SMT+DIP 20.6H

DDR5 288Pin Vertical SMT+DIP 20.6H Single buckle specification

DDR5 288Pin Vertical SMT+DIP 20.6H Single buckle specification

DDR5 SO DIMM 262Pin STD 5.2H

DDR5 SO DIMM 262Pin STD 5.2H

DDR5 SO DIMM 262Pin RVS 8.0H

DDR5 SO DIMM 262Pin RVS 8.0H

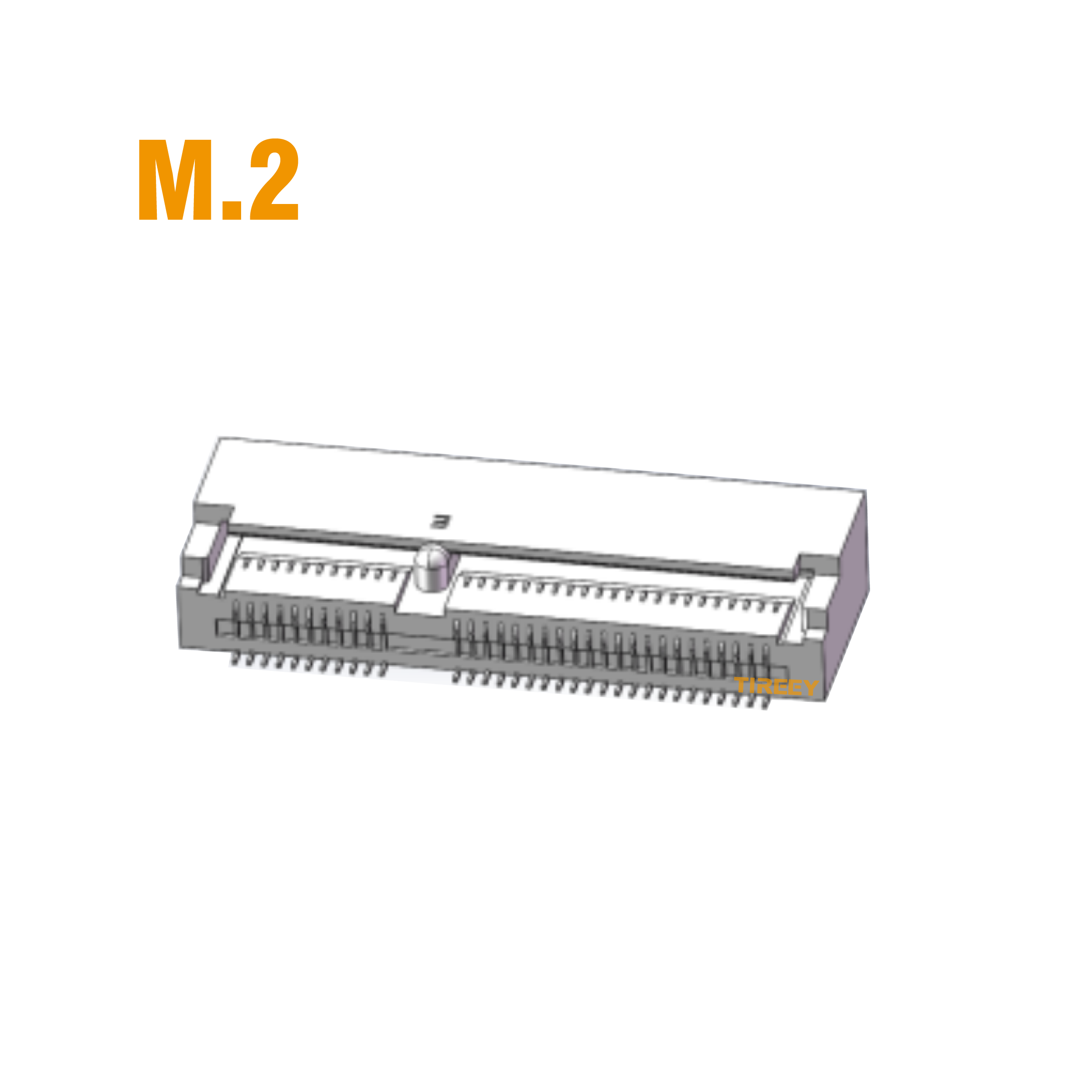

M.2 GEN4 H=8.5 A KEY CONN

M.2 GEN4 H=8.5 A KEY CONN

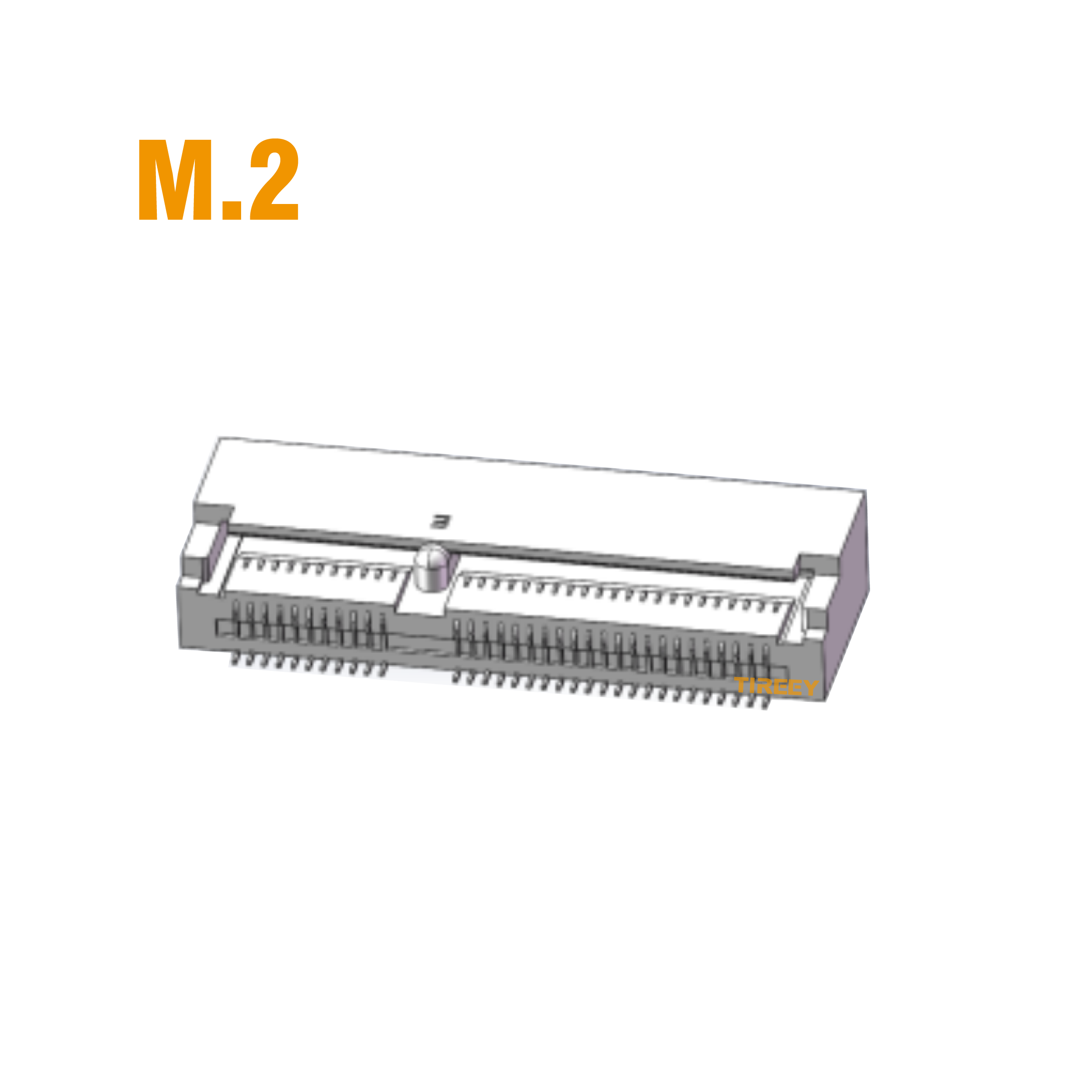

M.2 GEN4 H=4.0 M KEY CONN

M.2 GEN4 H=4.0 M KEY CONN

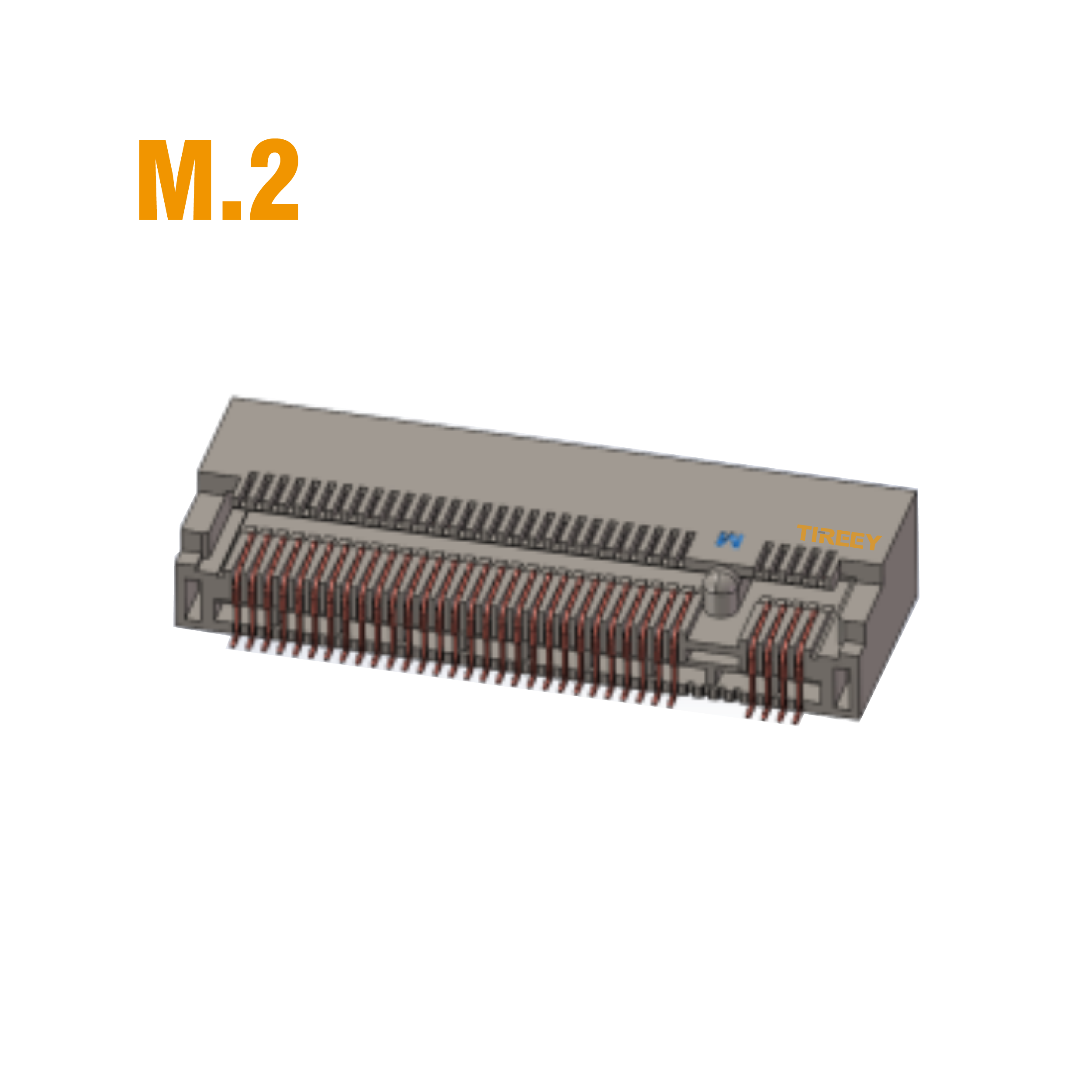

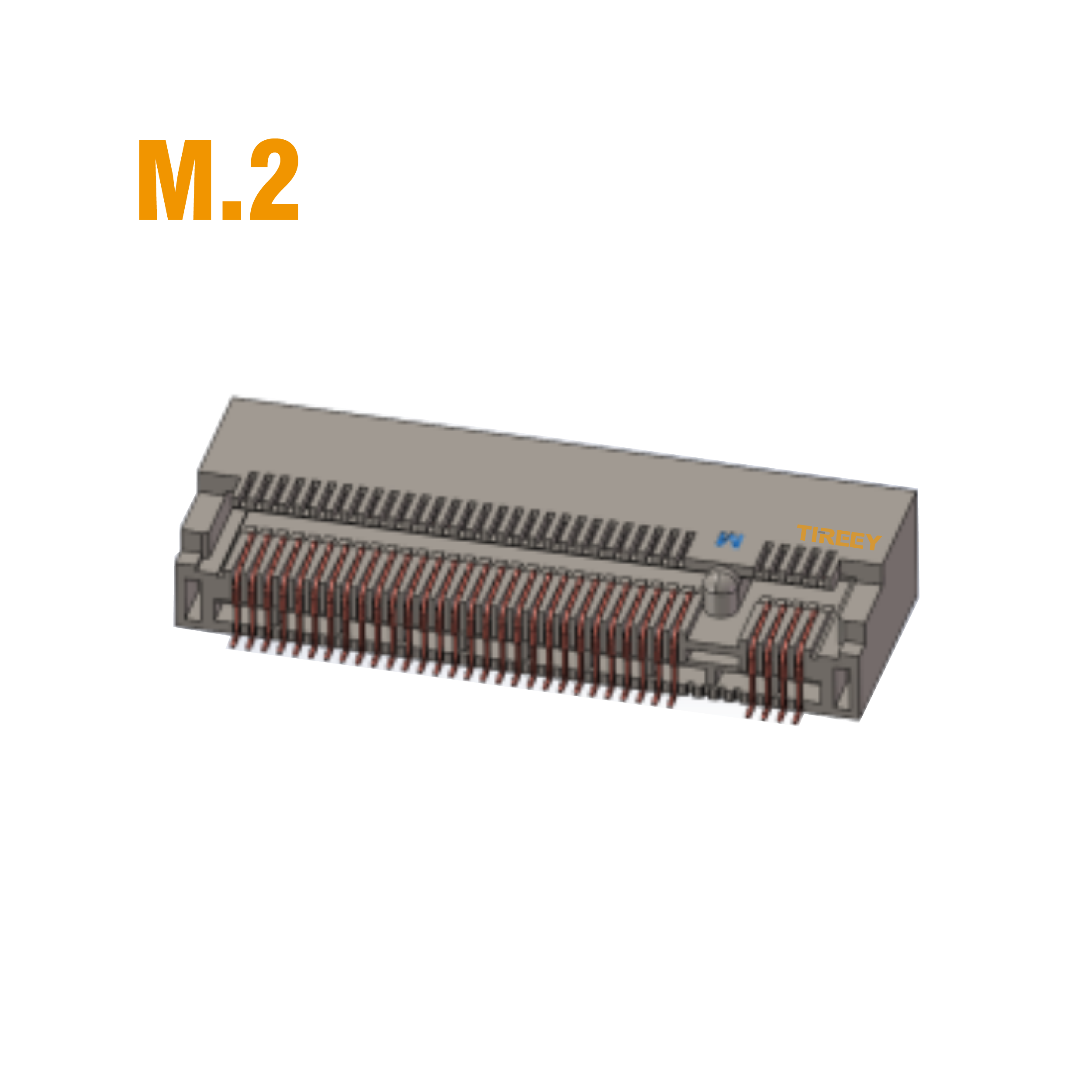

M.2 GEN4 H=4.0 E KEY CONN

M.2 GEN4 H=4.0 E KEY CONN

DDR4 288PIN DIP

DDR4 288PIN DIP

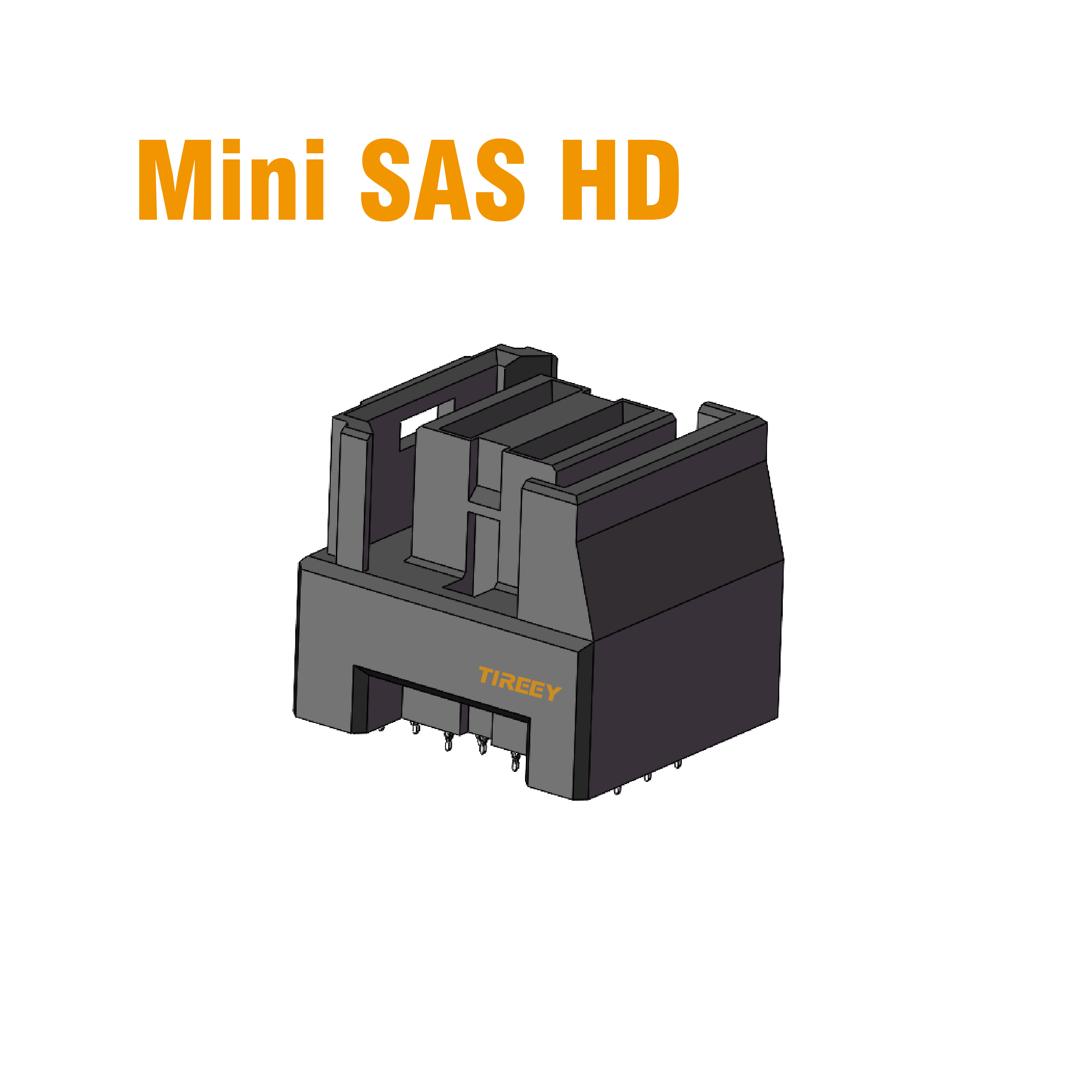

Mini SAS HD Vertical 36P Conn

Mini SAS HD Vertical 36P Conn

PCIE4.0 8X 98Pin SMT type

PCIE4.0 8X 98Pin SMT type

PCIE4.0 16X 164Pin Tail + Iron Case DIP Type

PCIE4.0 16X 164Pin Tail + Iron Case DIP Type

PCIE5.0 16X 164Pin SMT type

PCIE5.0 16X 164Pin SMT type

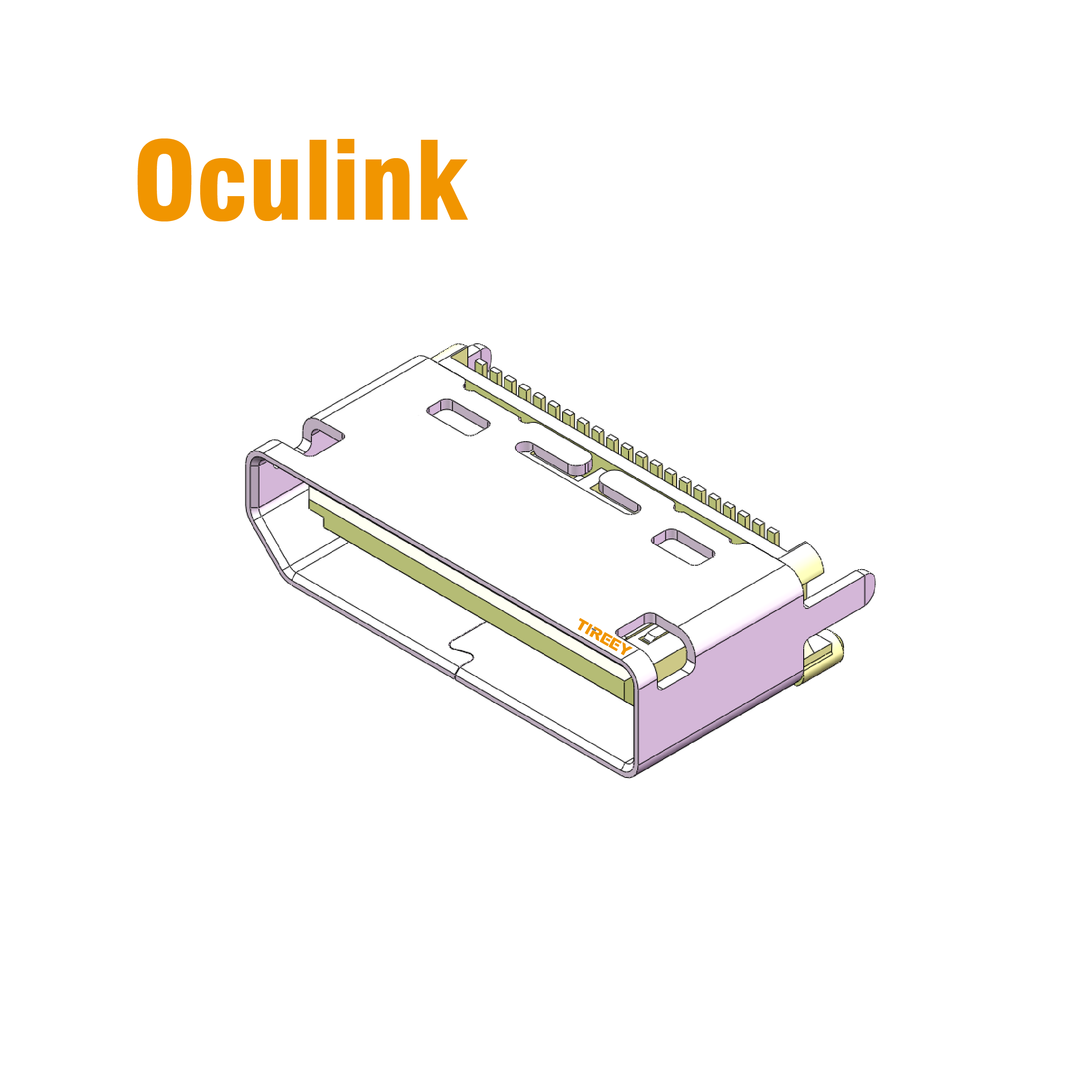

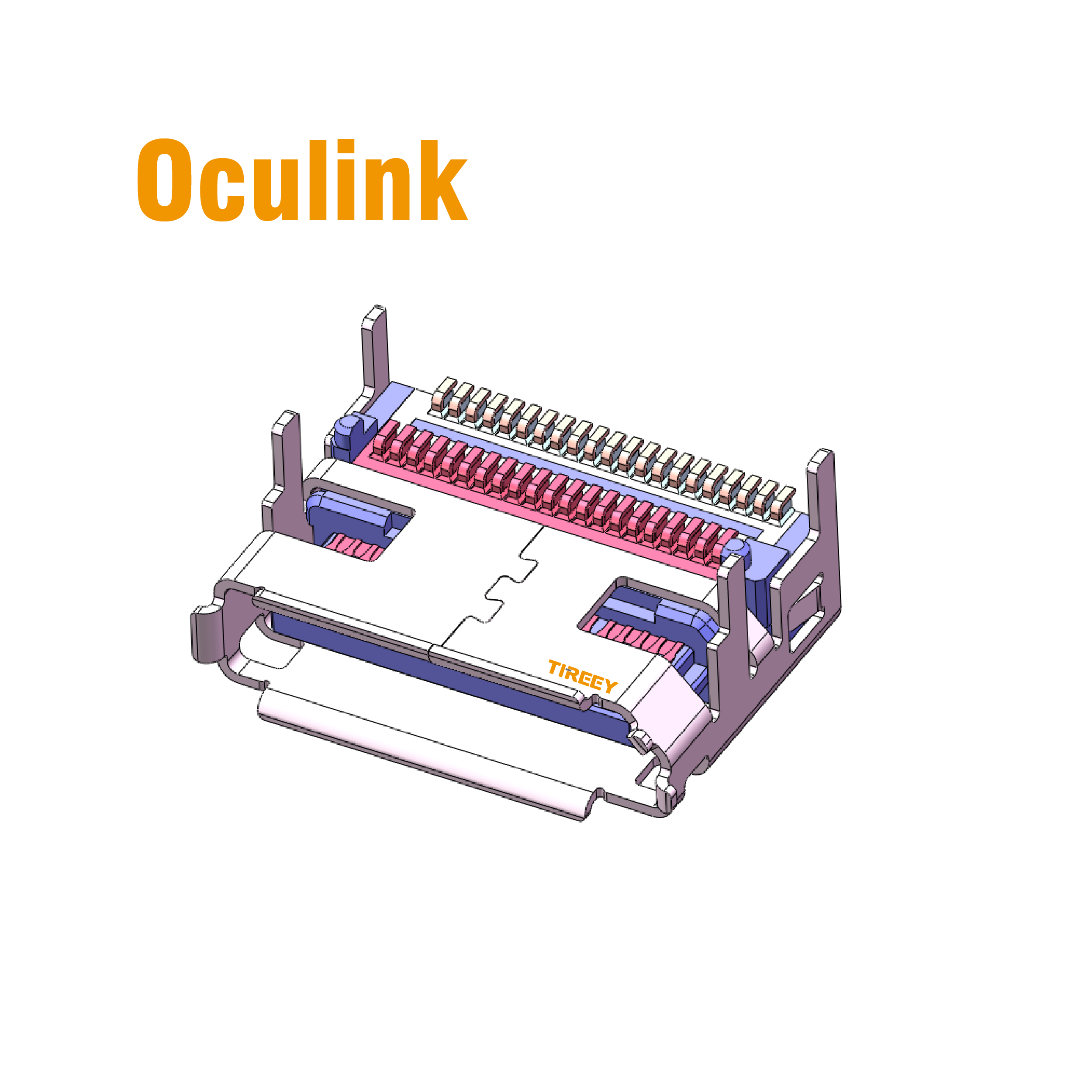

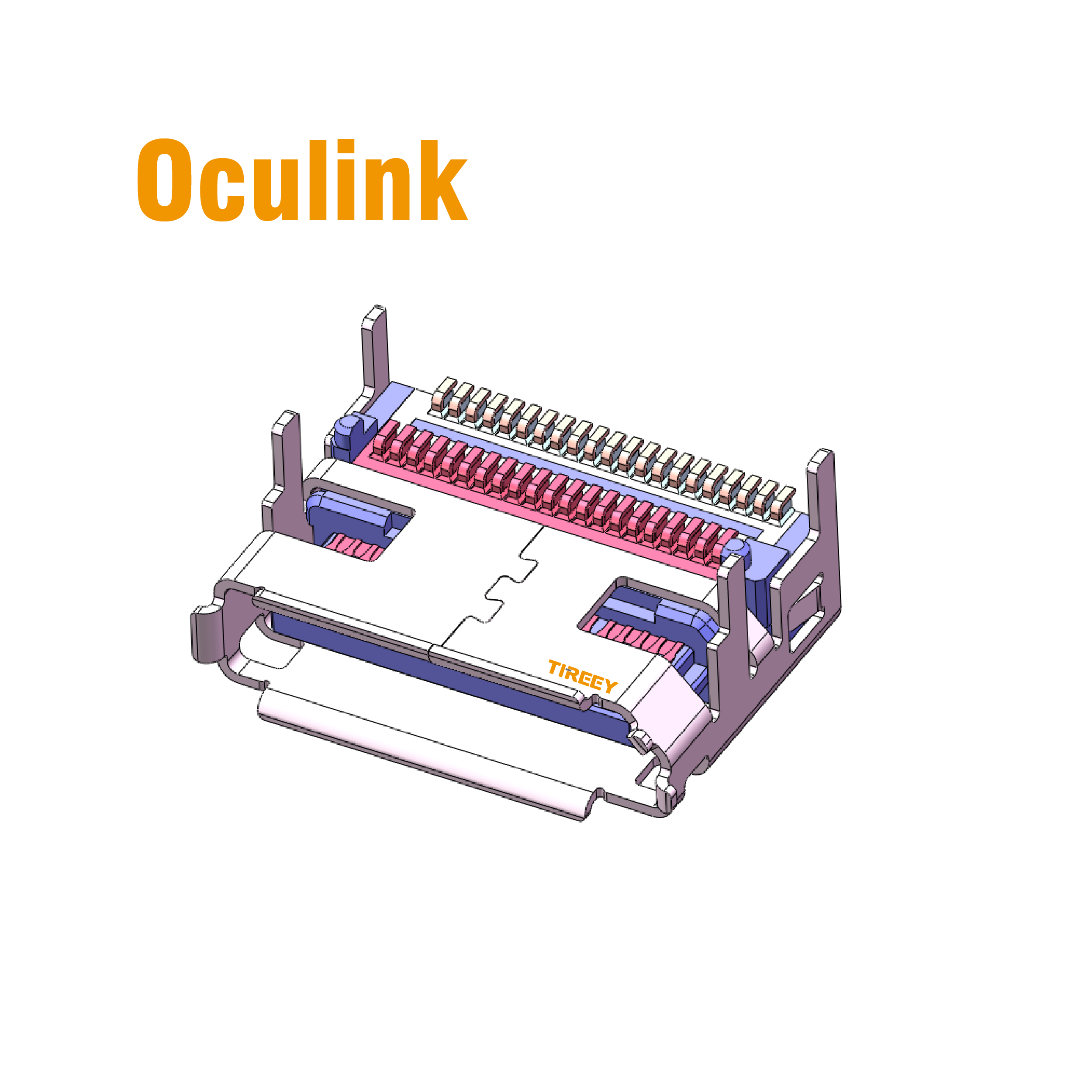

Oculink V/T 4x conn

Oculink V/T 4x conn

Oculink R/A 4x conn

Oculink R/A 4x conn

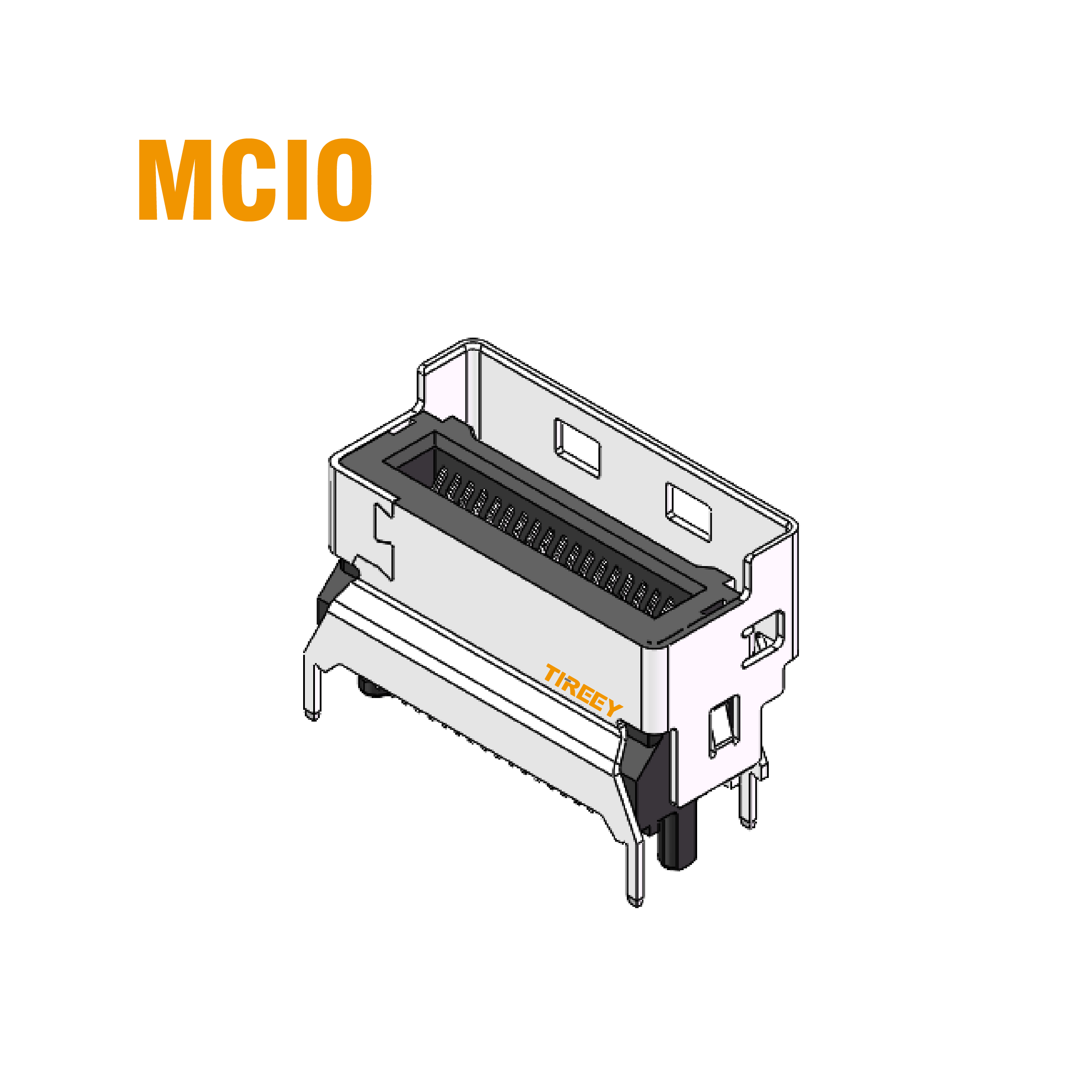

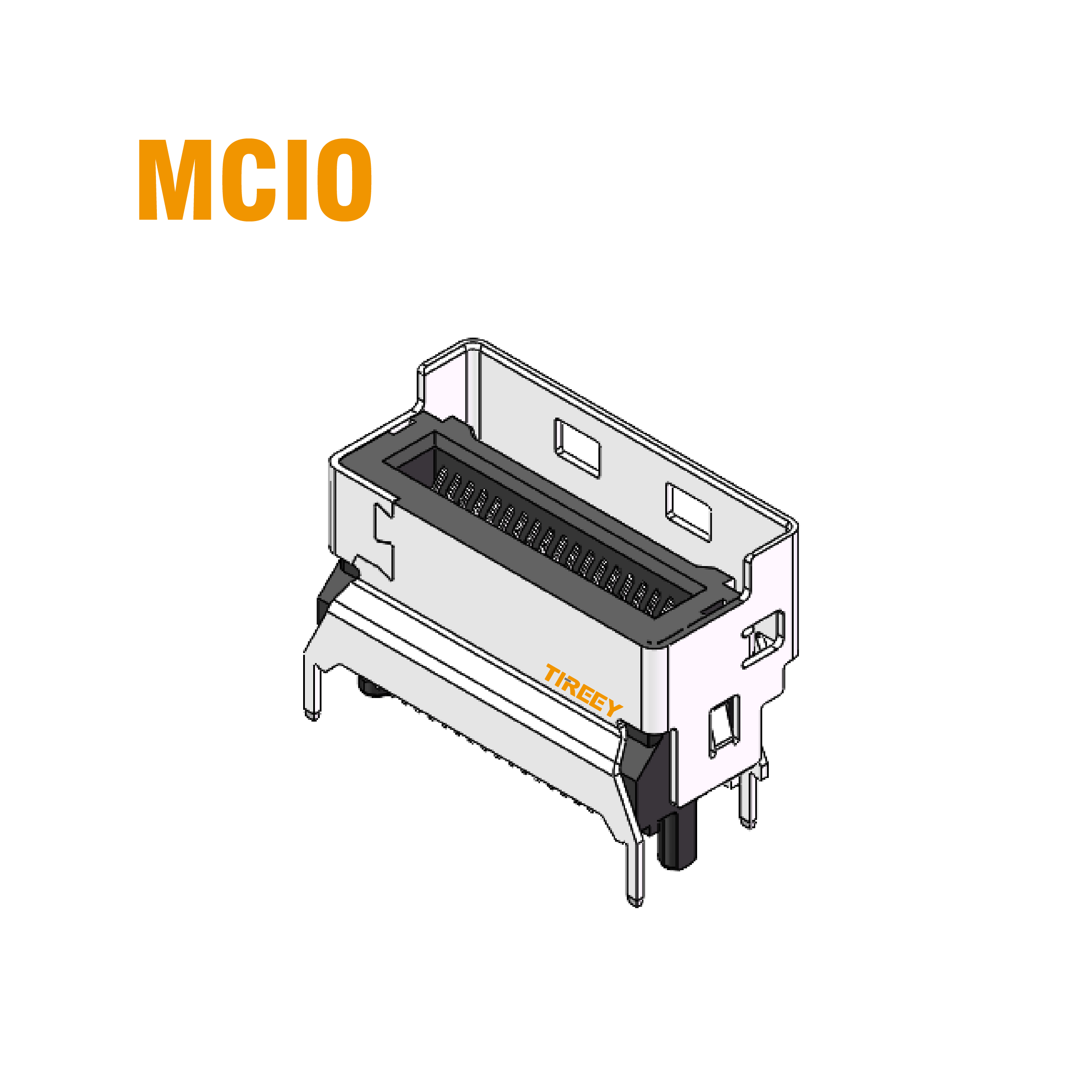

MINI COOL 38Pin 4X Vertical Conn

MINI COOL 38Pin 4X Vertical Conn

MINI COOL 74Pin 8X Horizontal Conn

MINI COOL 74Pin 8X Horizontal Conn

MINI COOL 74Pin 8X vertical Conn

MINI COOL 74Pin 8X vertical Conn

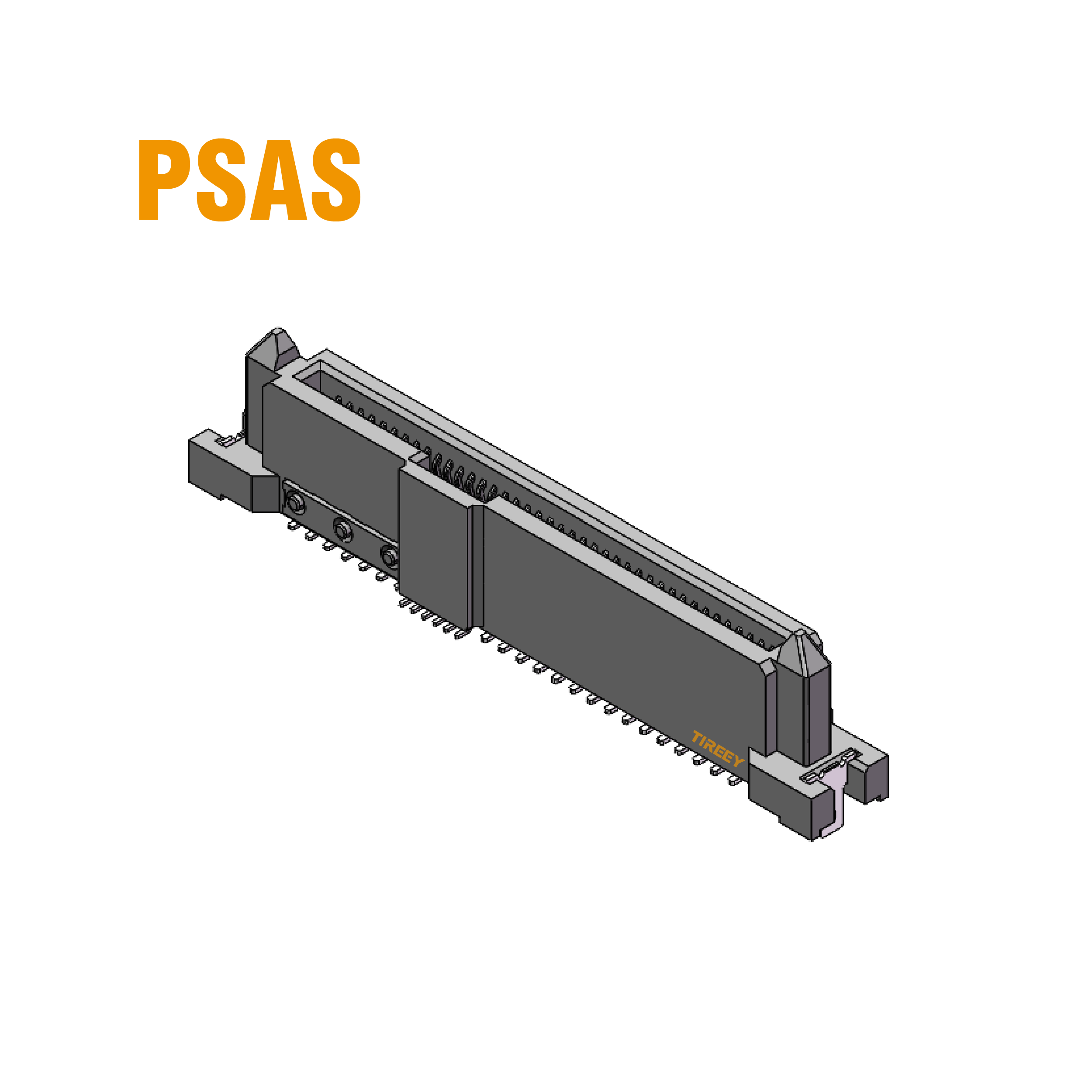

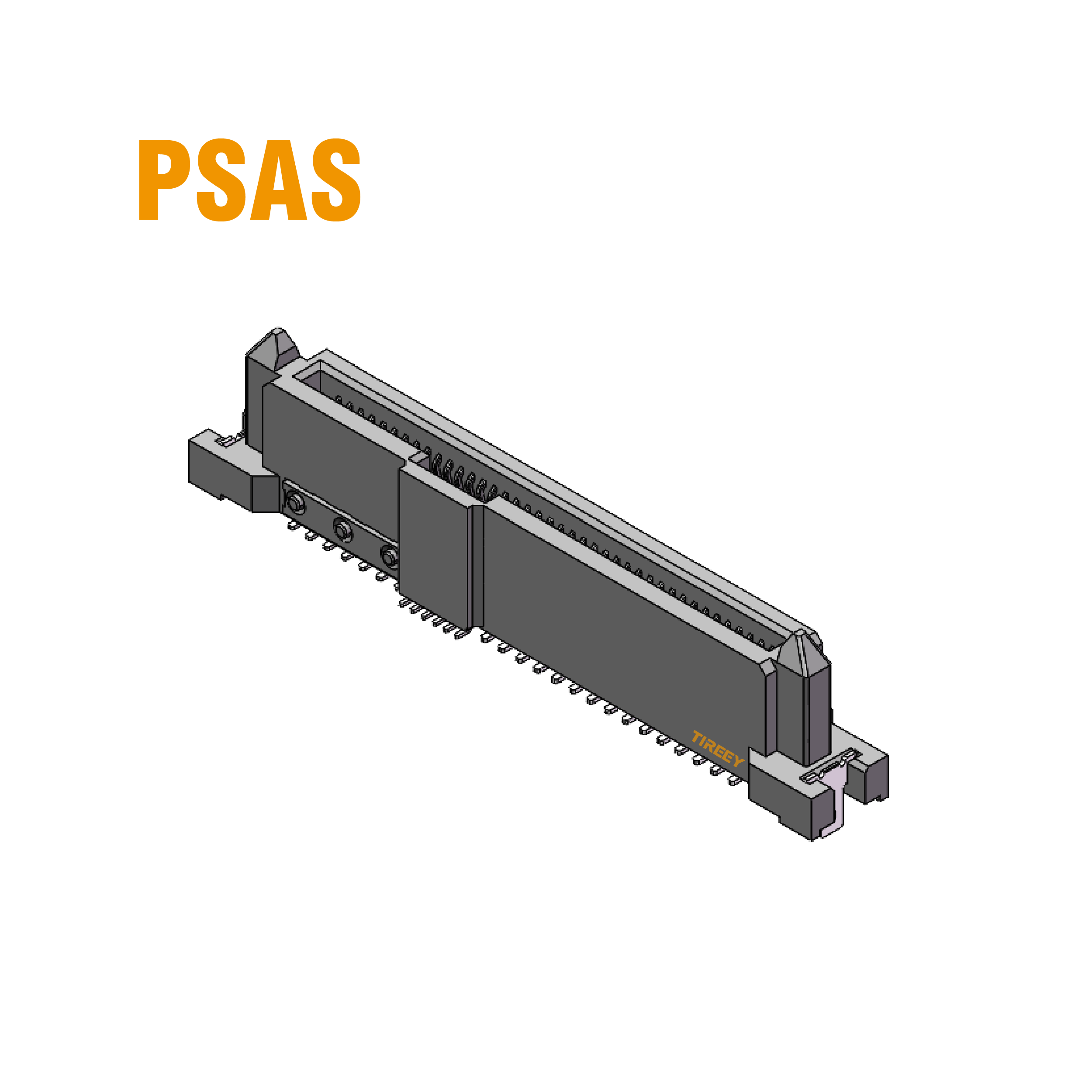

PSAS 68Pin for 24G PCIe/SAS

PSAS 68Pin for 24G PCIe/SAS

PSAS 68Pin for Pcle 5.0 Specification

PSAS 68Pin for Pcle 5.0 Specification

PSAS 68Pin for Pcle 5.0 Specification

PSAS 68Pin for Pcle 5.0 Specification

Gen Z4C + Vertical 168Pin

Gen Z4C + Vertical 168Pin

Gen Z4C + Splint Type 168Pin

Gen Z4C + Splint Type 168Pin

GenZ4C Vertical 140Pin No Iron Case

GenZ4C Vertical 140Pin No Iron Case

GenZ4C + Vertical 168Pin + Iron Case

GenZ4C + Vertical 168Pin + Iron Case

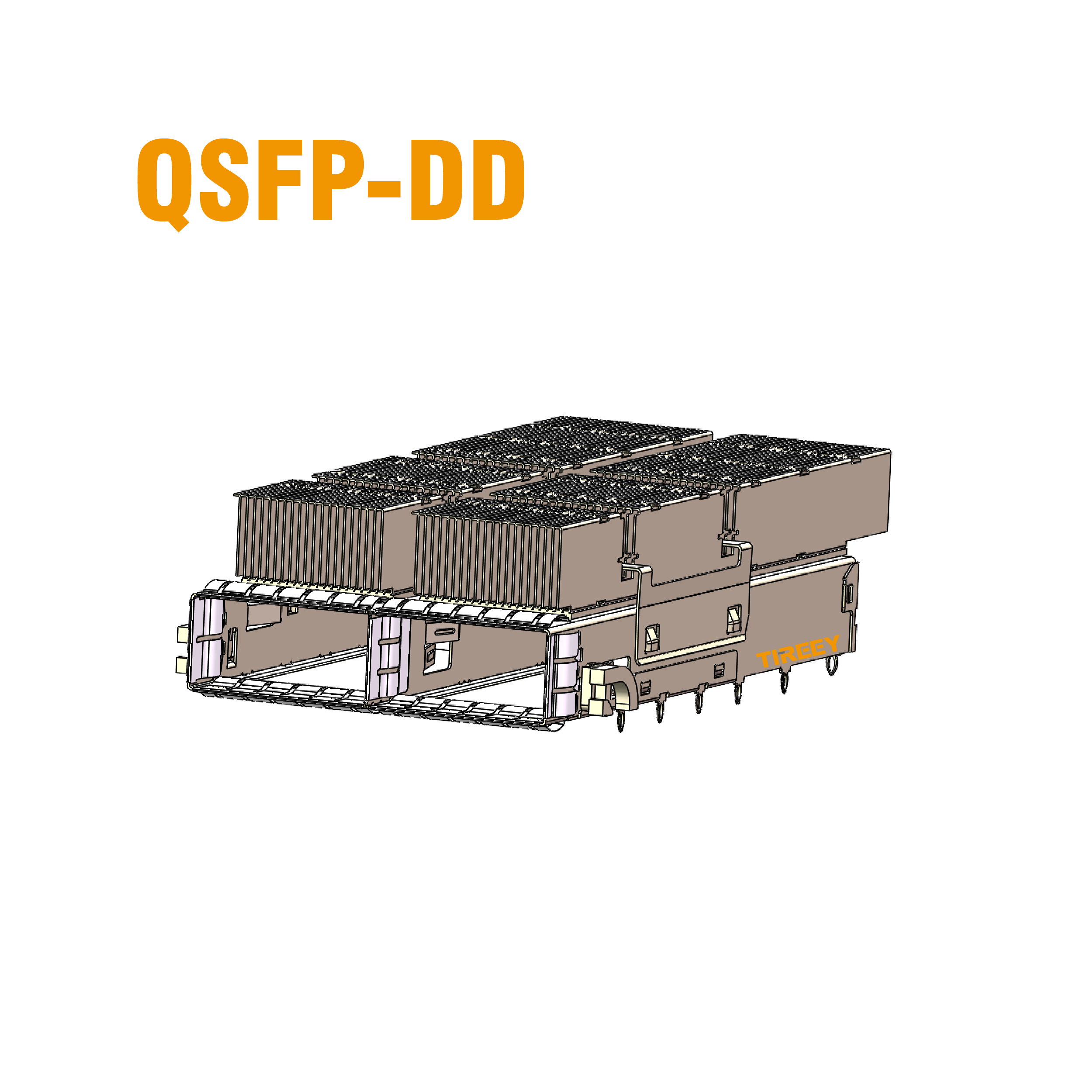

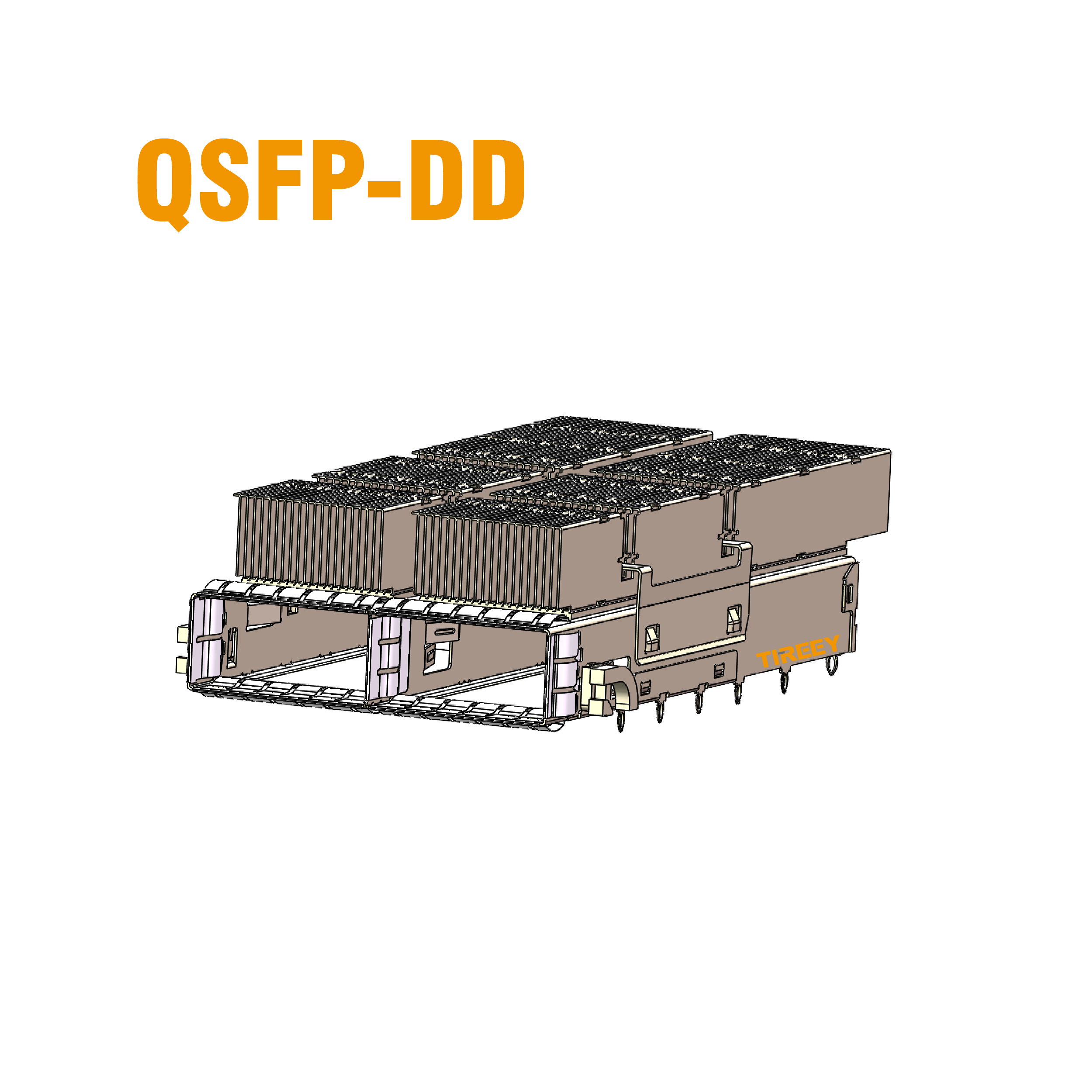

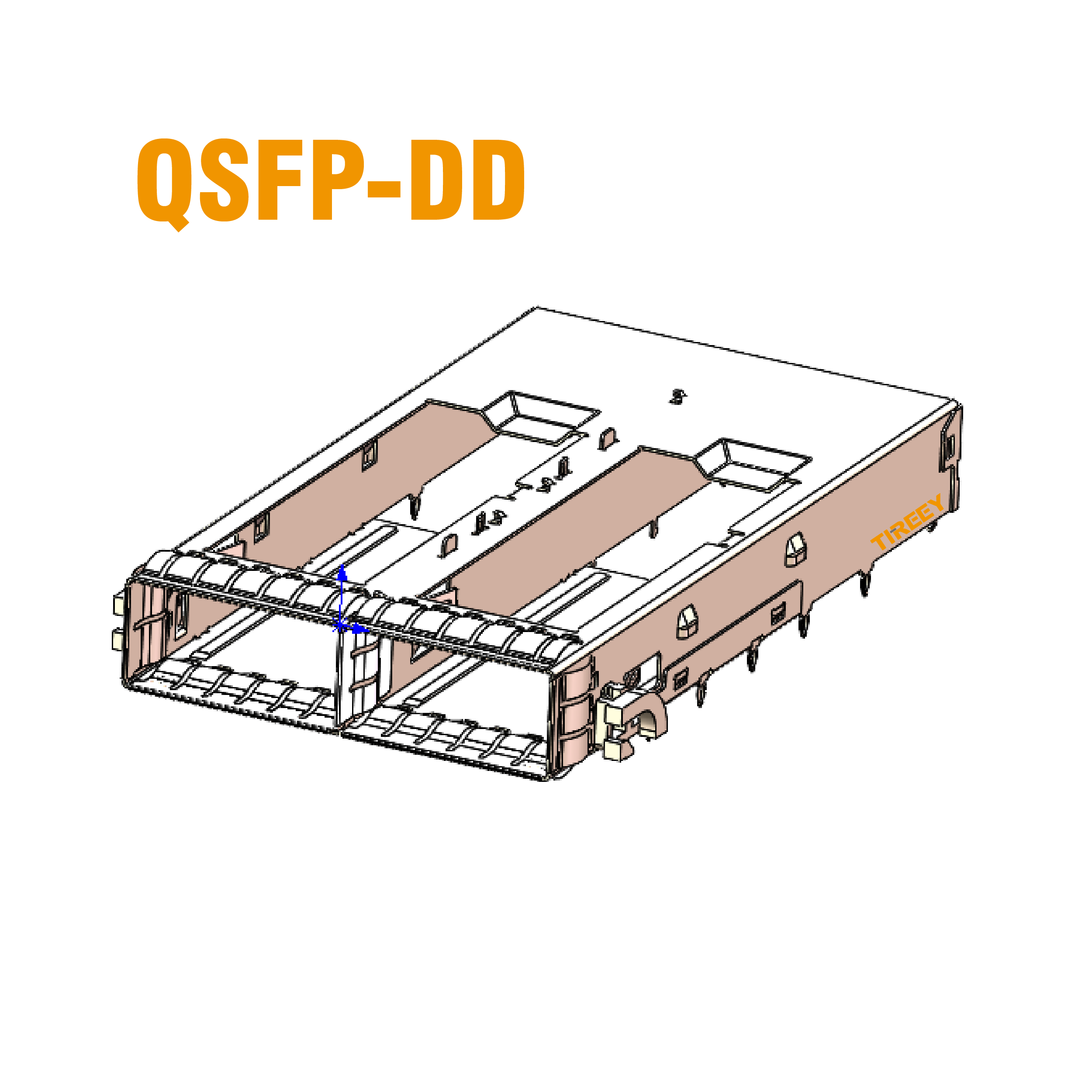

QSFP-DD 1*2 + Radiator

QSFP-DD 1*2 + Radiator

QSFP-DD 1*2 Cage

QSFP-DD 1*2 Cage

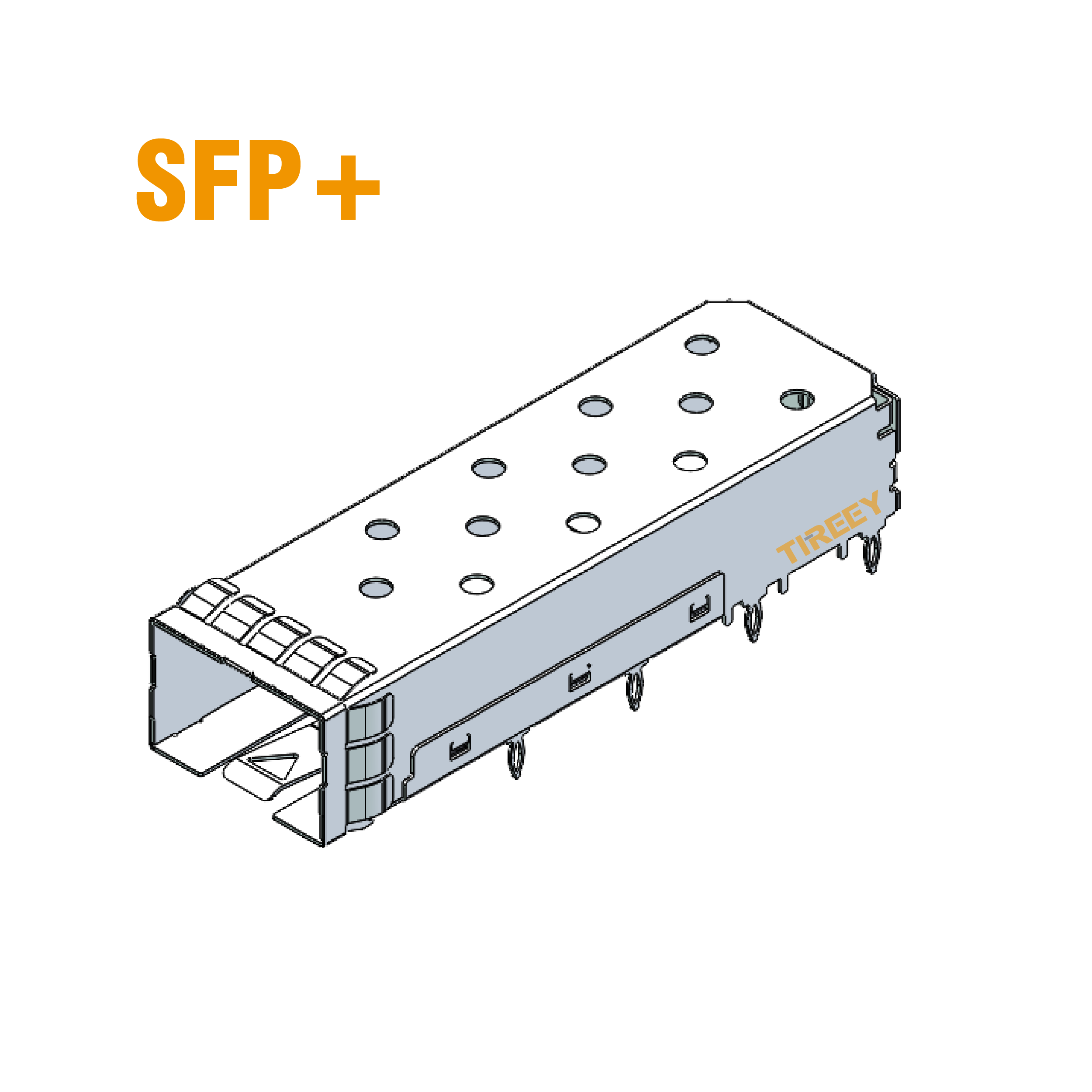

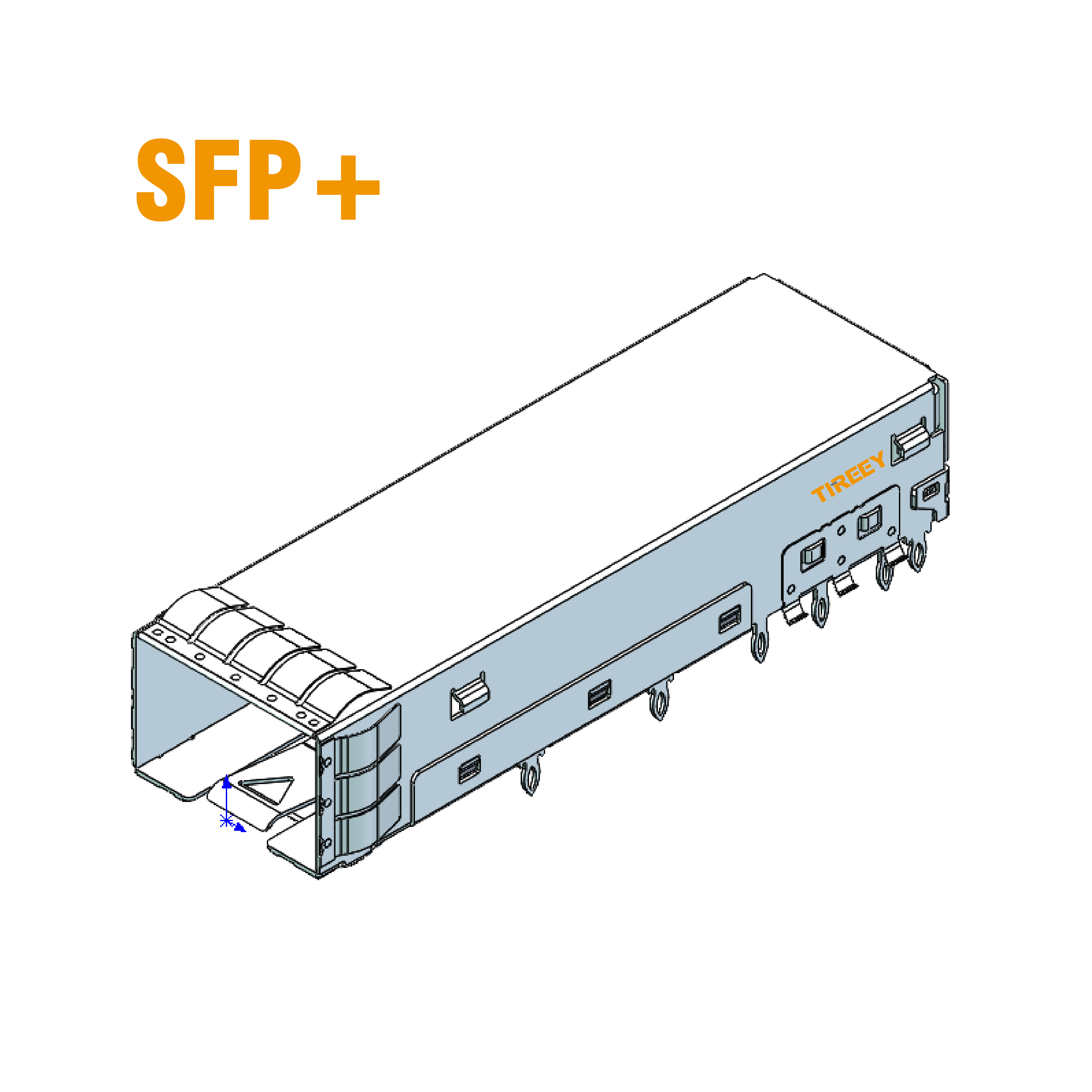

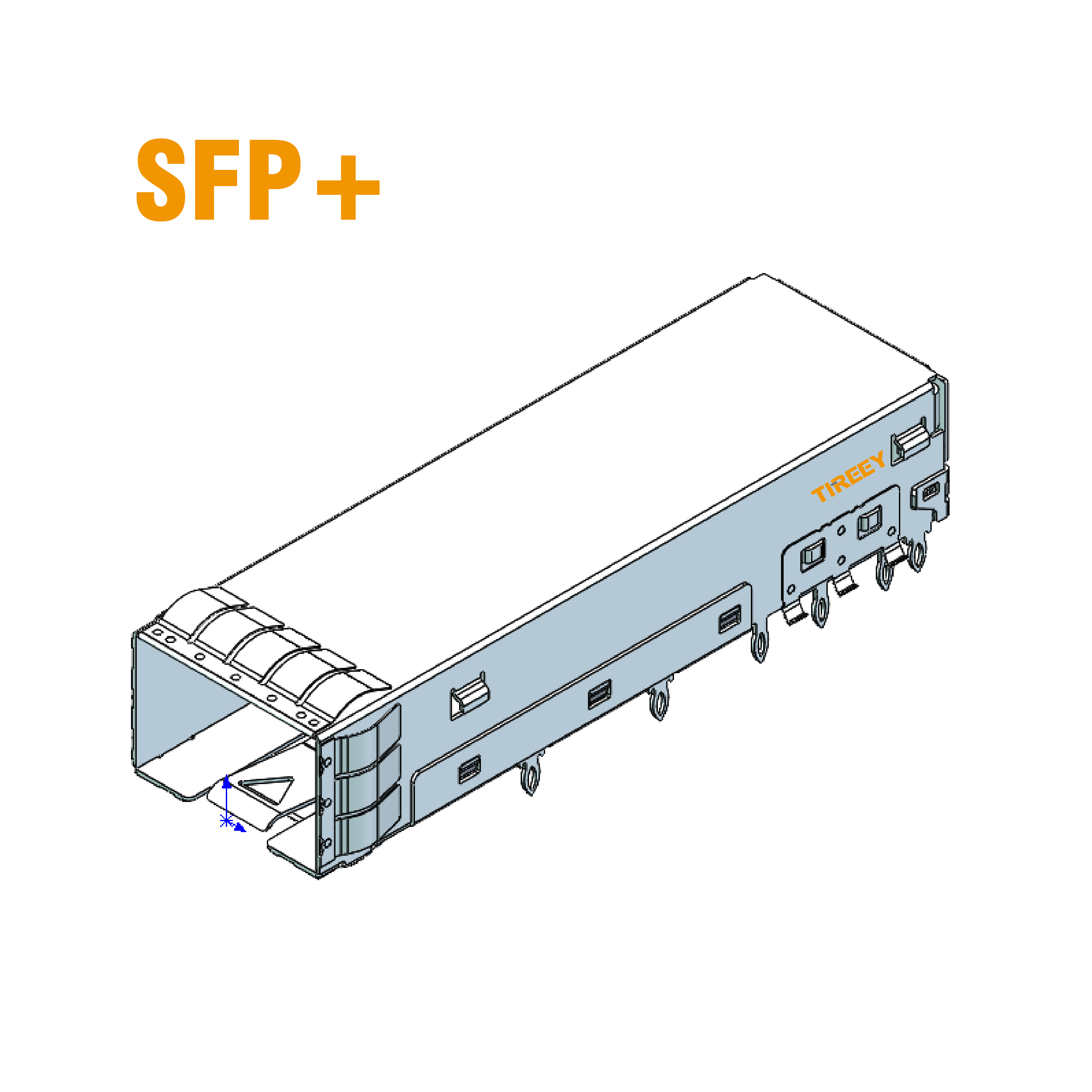

SFP+1*1 Crimp Pin

SFP+1*1 Crimp Pin

SFP28 1*1 Crimping With Double-sided Spring Clip

SFP28 1*1 Crimping With Double-sided Spring Clip